Certifications & Documents

Quality assurance and compliance, environmental and sustainability, gender pay gap report, terms and conditions of sale, code of conduct, dignity at work policy, equality and diversity policy

“Here at LIBERTY Speciality Steels, we produce steel products for some of the most demanding of applications, with our material being used in jet engines, helicopter drive systems, aircraft undercarriage, bearings systems and for oilfield exploration and management, to name just a few. As a result, we have to be obsessed about the quality of our products, their adherence to specification and their long term performance in use.”

What we do

Support the business in consistent approaches to product quality and customer requirements and the implementation of LIBERTY Speciality Steel’s strategy and objectives. These are assessed for compliance with international standards (e.g. NADCAP, ISO9001, IATF 16949, AS9100 series and ISO 17025), and formally certified by external approval bodies such as LRQA, UKAS and BSI. Review of and transition to new requirements, e.g. new revision of the standards, when necessary. Assist in the identification of improvement opportunities.

Business Management System

Accountable for the implementation of the Business Management System and its processes to ensure alignment with externally recognised standards and business strategy. Management and monitoring of the document control processes and its performance.

Administration of the database Achiever Sword Triangle with regards to user access, document control and problem solving.

Process Approach

Assistance in the adoption of the process approach when developing, implementing, and improving business processes. Support when establishing linkage between business processes and their interaction as well as identification of KPIs and objectives

Audits

Management of the extensive internal and external audit programme to monitor conformance with the Business Management System requirements and other relevant requirements such as Customer Specific Requirements or customer approvals, e.g. Rolls–Royce. The programme also assesses the effectiveness and the implementation of the Business Management System.

Support and monitoring of the investigation and actions taken to ensure timely close out of found non-conformances.

Training

Review and monitoring of the training of auditors to ensure competence and awareness.

Training in the use of the Achiever Sword Triangle database and other quality related courses such as RRES 90000 and automotive core tools.

Meet the team

Mark Hesling – QA Manager SSUK

mark.hesling@libertysteelgroup.com

+44 (0)1142 83 2311, +44 (0)1709 82 6759

Andrew Turton – Quality Lead – QA & Infrastructure SSUK

andy.turton@libertysteelgroup.com

+44 333 032 4494

Quality Team

Helen Bisby – Quality Systems Manager

helen.bisby@libertysteelgroup.com

Emma Baker-Barnes – Quality Systems Specialist

emma.baker-barnes@libertysteelgroup.com

Quality Policy

Quality Certificates

- BSI Certificate of Registration – AS9100 – Stocksbridge, including Advanced Machining Centre

- BSI Certificate of Registration – AS9100 – Engineering Bar, Rotherham

- BSI Certificate of Registration – AS9100 – Rotherham Steel and Bar

- BSI Certificate of Registration – AS9120 – Aerospace Service Centre Bolton

- BSI Certificate of Registration – AS9120 – Aerospace Service Centre Suzhou, China

- BSI Certificate of Registration – Occupational Health & Safety Management System ISO 45001:2018

- BSI Certificate of Registration – Environmental Management Systems – ISO 14001:2015

- LRQA – Certificate of Approval – IATF 16949:2016, Speciality Steel UK Limited, Rotherham Works, PO Box 50, Aldwarke Lane, Rotherham, S65 3SR, United Kingdom

- LRQA – Certificate of Approval – IATF 16949:2016, Speciality Steel UK Limited, All Saints Road, Wednesbury, WS10 9TS, United Kingdom

- LRQA – Certificate of Approval – IATF 16949:2016 Speciality Steel UK Limited Engineering Bar, Rotherham

- LRQA – Certificate of Approval, Rotherham Works – ISO 9001:2015

- LRQA – Certificate of Approval, All Saints Road, Wednesbury, WS10 9TS, United Kingdom – ISO 9001:2015

- LRQA – Certificate of Approval ISO 9001:2015 Speciality Steel UK Limited Engineering Bar, Rotherham

- BSI Certificate of Registration – Quality Management System, Narrow Strip – ISO 9001:2015

- UKAS testing laboratory number 4337 ISO/IEC 17025:2017 Expiry 30-04-2026 – Please see www.ukas.com for latest scope

- CARES BS4449 Certificate

- CARES ISO 9001:2015 Certificate

- CARES BES 6001 Issue 3.1 Certificate

Approvals

Rotherham

- Nadcap – Materials Testing (Certificate)

- Nadcap – Materials Testing – Certificate Extention

- Nadcap – Materials Testing (Scope of Accreditation)

- Nadcap – Heat Treating (Certificate)

- Nadcap – Heat Treating (Scope of Accreditation)

- Nadcap – NonDestructive Testing (Certificate)

- Nadcap – NonDestructive Testing (Scope of Accreditation)

- Rolls Royce – Certificate of Approval Rotherham Works

Stocksbridge

- Nadcap – Materials Testing (Certificate)

- Nadcap – Materials Testing – Certificate Extention

- Nadcap – Materials Testing (Scope of Accreditation)

- Nadcap – Heat Treating (Certificate)

- Nadcap – Heat Treating (Scope of Accreditation)

- Nadcap – NonDestructive Testing (Certificate)

- Nadcap – NonDestructive Testing (Scope of Accreditation)

- Rolls Royce – Certificate of Approval Stocksbridge Works

- BSI PED Specific Materials Assessment – Speciality Steel UK Limited, 7 Fox Valley Way, Stocksbridge, Sheffield, S36 2JA, United Kingdom

- Rolls Royce – Certificate of Approval Bolton

LIBERTY Speciality Steels is committed to meeting the requirements of relevant legislation in the countries and regions in which it operates, to the efficient use of natural resources and energy, and to reducing continuously the environmental impact of its operations and products through the adoption of sustainable practices to protect the environment. These commitments are integral to the LIBERTY Steel UK GREENSTEEL Vision.

LSS Environment and Energy Policy Statement r7 May 2022

LSS Sustainability Policy Statement r4 May 2022

Policy Principles

In implementing the Policy the following key principles will be demonstrated:

Management system

An effective environmental and sustainability management system will be maintained, and will ensure awareness and encourage every employee to act in an environmentally responsible and sustainable manner.

Continuous improvement

The environmental impact of processes and products will be assessed and continuous improvement will be a key business objective

Climate change

Speciality Steels will be part of the solution to climate change and will achieve a leading position within the steel industry by minimising its greenhouse gas emissions and developing products that help to reduce emissions from the rest of society.

Sustainable use of resources

Efficient use will be made of energy, raw materials and water through adoption and sharing of good practice.

Life Cycle of Products

The reuse and recycling of Speciality Steels products will be promoted and the environmental effects of products throughout their life-cycle will be communicated to customers. Our Steel has over 95% recycled content. LCA for our products will be developed to demonstrate the sustainability benefits of the EAF steelmaking process.

Monitoring and reporting

Environmental and energy performance will be monitored and audited and progress in meeting high level Policy objectives and improvement targets will be recorded and reported.

Sustainable procurement

Our direct influence in the supply chain only extends to our immediate suppliers. Key suppliers and contractors will be encouraged to behave in an environmentally responsible manner in line with the principles set out within this Policy. To this end, all suppliers will be required to have equivalent and proportionate quality, environmental and health and safety certifications. We are able to trace all our steelmaking raw materials back to the place of production.

Local communities

Communities in the locality of its sites will be actively engaged by Speciality Steels so that it can understand and seek to address their concerns in relation to environmental issues.

Supporting Biodiversity

Wildlife habitats in and around Speciality Steels sites will be respected and, where opportunities arise to do so in a way that is conducive to business operations, they will be progressively enhanced for the benefit of nature.

Recycled Content and Resource Efficiency Statement

GREENSTEEL Vision

EAF Steel Recycled Content

LIBERTY Speciality Steels uses Electric Arc Furnaces to melt scrap and produce new steel products, Steel recycling is one of the few recycling operations which actually upgrades the material so that a tin can one day could be part of an aircraft tomorrow.

95.3% Recycled Steel Content

In 2016 The Steel produced at Rotherham had a 95.3% recycled scrap content, this uses significantly less energy than alternative routes, releases significantly less carbon dioxide and does not require the mining of iron ore.

GREENSTEEL in Action

The Steelmaking process uses significant tonnages of raw materials in the process and the steelmaking equipment. LIBERTY Speciality Steels applies continuous improvement techniques and Environmental management systems (ISO14001) to ensure high levels of material resource efficiency are achieved. The waste hierarchy is rigorously applied and we recycle a significant percentage of our wastes. We ensure that we minimise material use through Environmental Objectives

Material Use Minimisation

Oil use – minimisation of oil use by use of planned maintenance and incident root cause analysis. Water use – use of re -circulatory systems to ensure minimum abstraction of water from the river.

Waste Generation Minimisation

Steel making SLAG – This is used as part of the steelmaking process, 100% of primary steelmaking slag is recycled for use as road stone. Primary Fume Extraction Systems Dust – This dust from the filter plants contains high levels of Zinc, the dust is processed to recycle the zinc. Mill Scale and Refractory Fines – This is blended and used in brick making. Recyclable materials – Concrete, Plastic, Wood, paper, metal are all collected and recycled.

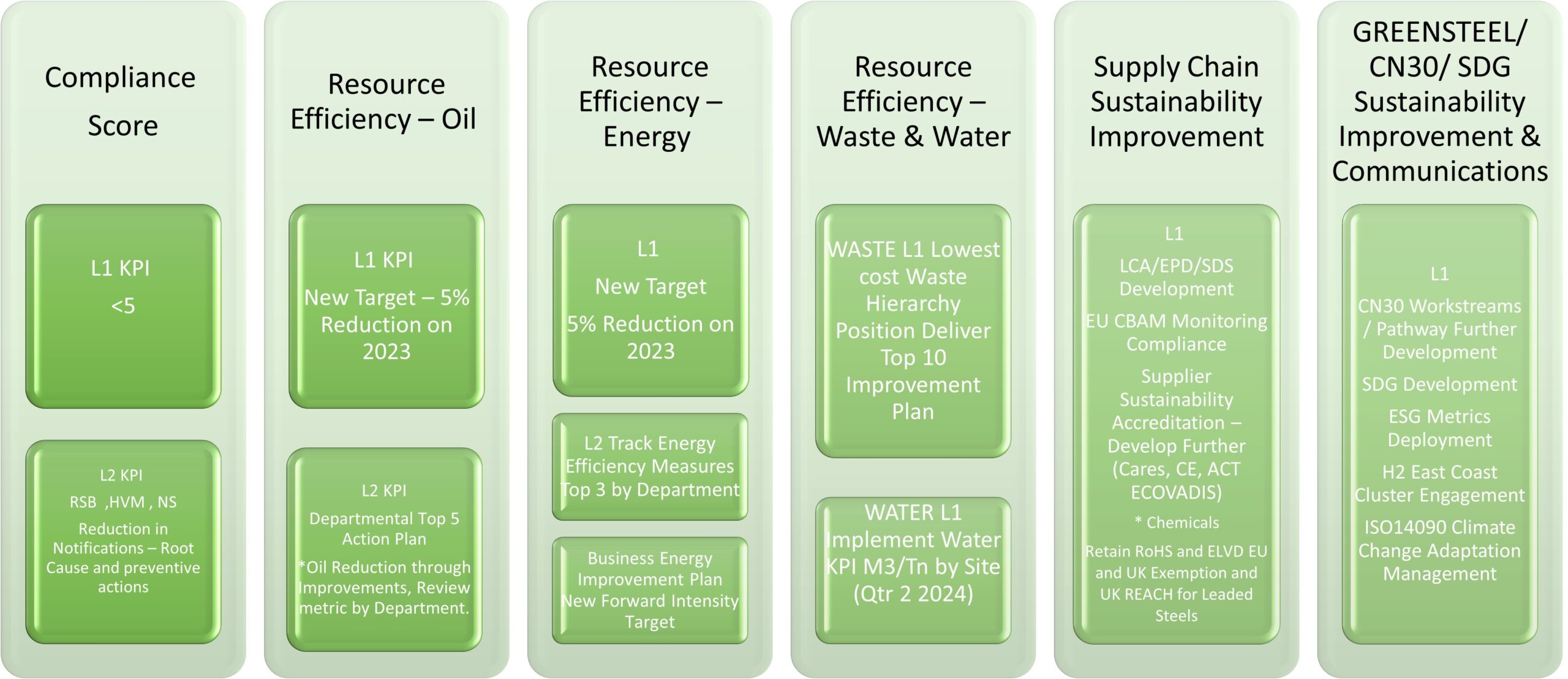

Environmental and Sustainability Objectives and KPIs 2024

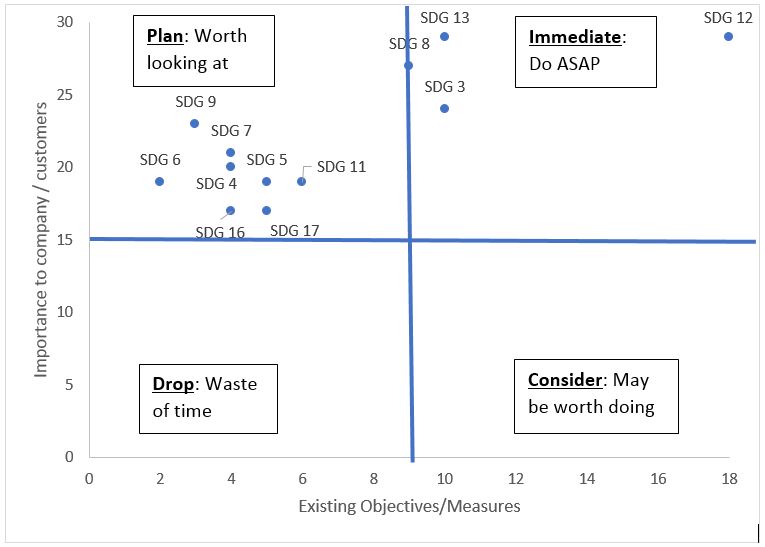

Materiality Assessment

The below graph shows the sustainability issues that are important to our key stakeholders.

| Goal 3 – Ensure healthy lives and promote well-being for all at all ages |  |

| Goal 8 – Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all |  |

| Goal 12 – Ensure sustainable consumption and production patterns |  |

| Goal 13 – Take urgent action to combat climate change and its impacts* |  |

LIBERTY Steel UK businesses, products and markets overview

Liberty Speciality Steels Conflict on Minerals Statement 2023

Sustainability Performance Cockpit – 2021 vs 2022

LSS Control of Asbestos Policy Statement r1 Aug 2017

LSS Control of Radiation in Products Statement r2 July 2022

LSSUK ELV Directive Statement r1

LSSUK Proposition 65 Statement r1

LSSUK REACH Substances of Very High Concern r5

LSSUK Recycled Content and Resource Efficiency Statement r2

LSSUK Statement on Restriction of Hazardous Substances Directive r2

SCIP Database – Bar products – registration information for customers V2 June 2021

SCIP Database – Strip products – registration information for customers V2 June 2021

The Sustainability of Steel Manufacturing – Liberty Speciality Steels

The primary commitment of the team at LIBERTY Steel Newport is to fully satisfy the needs and expectations of our customers in a safe and responsible manner.

The LIBERTY Steel Newport has a proud tradition of producing quality Hot Rolled Coil (HRC) with a history spanning over 40 years.

Our HRC is quality assured through our commitment to critical control of; raw material procurement, the manufacturing process and final testing, including as appropriate specific inspection “type 3.1” (EN 10204:2004), structural grades are additionally CE-marked.

Our Quality Management System fully satisfies the requirement of:

BS EN 9001 – View Certificate

This system is maintained and continuously improved by a planned cycle of internal audits, a twice yearly management review and third-party audits.

Our Factory Production Control is independently verified as conforming with the requirements of BS EN 10025 Part 2 Non-alloy structural steels – View Certificate

BS EN 10025, CE marked within the EU – View Certificate

- UKCA Declaration of Performance S235J0

- UKCA Declaration of Performance S235J2

- UKCA Declaration of Performance S235JR

- UKCA Declaration of Performance S275J0

- UKCA Declaration of Performance S275J2

- UKCA Declaration of Performance S275JR

- UKCA Declaration of Performance S355J0

- UKCA Declaration of Performance S355J2

- UKCA Declaration of Performance S355JR

- CE Declaration of Performance S235J0

- CE Declaration of Performance S235J2

- CE Declaration of Performance S235JR

- CE Declaration of Performance S275J0

- CE Declaration of Performance S275J2

- CE Declaration of Performance S275JR

- CE Declaration of Performance S355J0

- CE Declaration of Performance S355J2

- CE Declaration of Performance S355JR

Policies

Certificates

- ABS Certificate

- AD 2000 Merkblatt

- DNV Cert 2023

- 9001 QMS

- 9001 (EU) QMS

- NHSS 3B

- 14001 EMS

- CE (EU) CPR Cert

- UKCA CPR Cert

- LR MQS Cert

- LR MSS (Works Approval) cert

- BES 6001 Sustainability Cert

Declaration of Performance (DOP)

UKCA Declarations of Performance (DOP)

EN10025-2 Structural Steel

- Liberty DOP_S235J0-1.0114 CA22

- Liberty DOP_S235J2-1.0117 CA22

- Liberty DOP_S235JR-1.0038 CA22

- Liberty DOP_S275J0-1.0143 CA22

- Liberty DOP_S275J2-1.0145 CA22

- Liberty DOP_S275JR-1.0044 CA22

- Liberty DOP_S355J0-1.0553 CA22

- Liberty DOP_S355J2-1.0577 CA22

- Liberty DOP_S355JR-1.0045 CA22

- Liberty DOP_S355K2-1.0596 CA22

EN10025-3 Normalised & Normalised Rolled

- Liberty DOP_S275N-1.0490 CA22

- Liberty DOP_S275NL-1.0491 CA22

- Liberty DOP_S355N-1.0545 CAS22

- Liberty DOP_S355NL-1.0546 CA22

EN10025-4 TMCR

- Liberty DOP_S275M-1.8818 CA22

- Liberty DOP_S275ML-1.8819 Ca22

- Liberty DOP_S355M-1.8823 CA22

- Liberty DOP_S355ML-1.8834 CA22

EN10025-5 Weathering

- Liberty DOP_S355J0W-1.8959 Ca22

- Liberty DOP_S355J2W-1.8965 CA22

- Liberty DOP_S355K2W-1.8967 CA22

- Liberty DOP_S355J4W-1.8787 CA22

- Liberty DOP_S355J5W-1.8991 CA22

CE Declaration of Performance (DOP)

EN10025-2 Structural Steel

- Liberty DOP_S235J0-1.0114 CE20

- Liberty DOP_S235J2-1.0117 CE20

- Liberty DOP_S235JR-1.0038 CE20

- Liberty DOP_S275J0-1.0143 CE20

- Liberty DOP_S275J2-1.0145 CE20

- Liberty DOP_S355J0-1.0553 CE20

- Liberty DOP_S355J2-1.0577 CE20

- Liberty DOP_S355JR-1.0045 CE20

- Liberty DOP_S355K2-1.0596 CE20

EN10025-3 Normalised & Normalised Rolled

- Liberty DOP_S275N-1.0490 CE20

- Liberty DOP_S275NL-1.0491 CE20

- Liberty DOP_S355N-1.0545 CE20

- Liberty DOP_S355NL-1.0546 CE20

EN10025-4 TMCR

EN10025-5 Weathering

Quality Certificates & Approvals

- LRQA approval certificate

- ISO 9001:2015 approval certificate to 2021

- EC Certificate & Declaration of Conformity for CE Marking

- Lloyds Register approval certificate

- DNV.GL approval certificate

- Material Origin Statement

- Radioactivity Statement

- Statement of Restriction of Hazardous Substances Directive (RoHS)

- Conflict Minerals Statement

- REACH Statement

Declaration of Performance

English

German

Environmental Policy

ISO 14001:2015 approval certificate to 2022