- 23 August 2023

- Community

LIBERTY Speciality Steels and the University of Sheffield launch Carbon Capture Trials

On August 23rd, LIBERTY Speciality Steels, in conjunction with the University of Sheffield, started carbon capture trial at the LIBERTY Brinsworth site, on a hot rolling mill furnace. This trailblazing initiative aims to combat climate change by curbing carbon dioxide (CO2) emissions stemming from extensive industrial sources.

The concept of carbon capture involves capturing CO2 emissions directly from their point of origin, subsequently repurposing the captured carbon dioxide for the production of alternative fuels, base chemicals, cosmetics, or securely storing it underground. There are different carbon capture technologies, but this particular one is the most innovative and effective.

Through the deployment of this advanced technique, LIBERTY and the University of Sheffield are working together to achieve substantial reductions in the carbon footprint associated with large-scale industrial operations. This trial is being conducted as part of the SUSTAIN Steel Research Hub project, a collaborative venture led by Swansea University. The project brings together more than twenty partners across the UK steel industry: primary manufacturers, supply chain, trade bodies, academic experts and research organisations working together on a seven-year research programme to transform the UK steel sector into a carbon neutral, zero waste, digitally agile industry that is responsive to the fast-changing needs of customers.

Ed Heath-Whyte, LIBERTY Steel UK Head of Environment and Sustainability said:

“The importance of Research and Innovation in the fight to prevent climate change is at its height now. The work we do now and have done in the last 10 years are the future technologies that we will be implementing over the next decades impacting the reduction in CO2 emissions.

Our Brinsworth Strip Mills site has a long history of innovation and trial work. The FLuRefin unit built by AESSEAL was setup successfully and trial started. By focusing on applying this state-of-the-art technology to a hot rolling mill furnace, the trials aim to validate its effectiveness. If successful, this practice has the potential to be scaled across the UK, heralding a transformative shift within the industry”.

Peter Styring, Professor of Chemical Engineering & Chemistry at The University of Sheffield said: “Great to see our research starting to make an impact. Thanks to all at Liberty Steel for having us on-site for the test flight on a live stack! The next task is to balance the flow into the unit. Looking good so far and importantly learning new improvements”.

Tags

Latest News

View All News

News

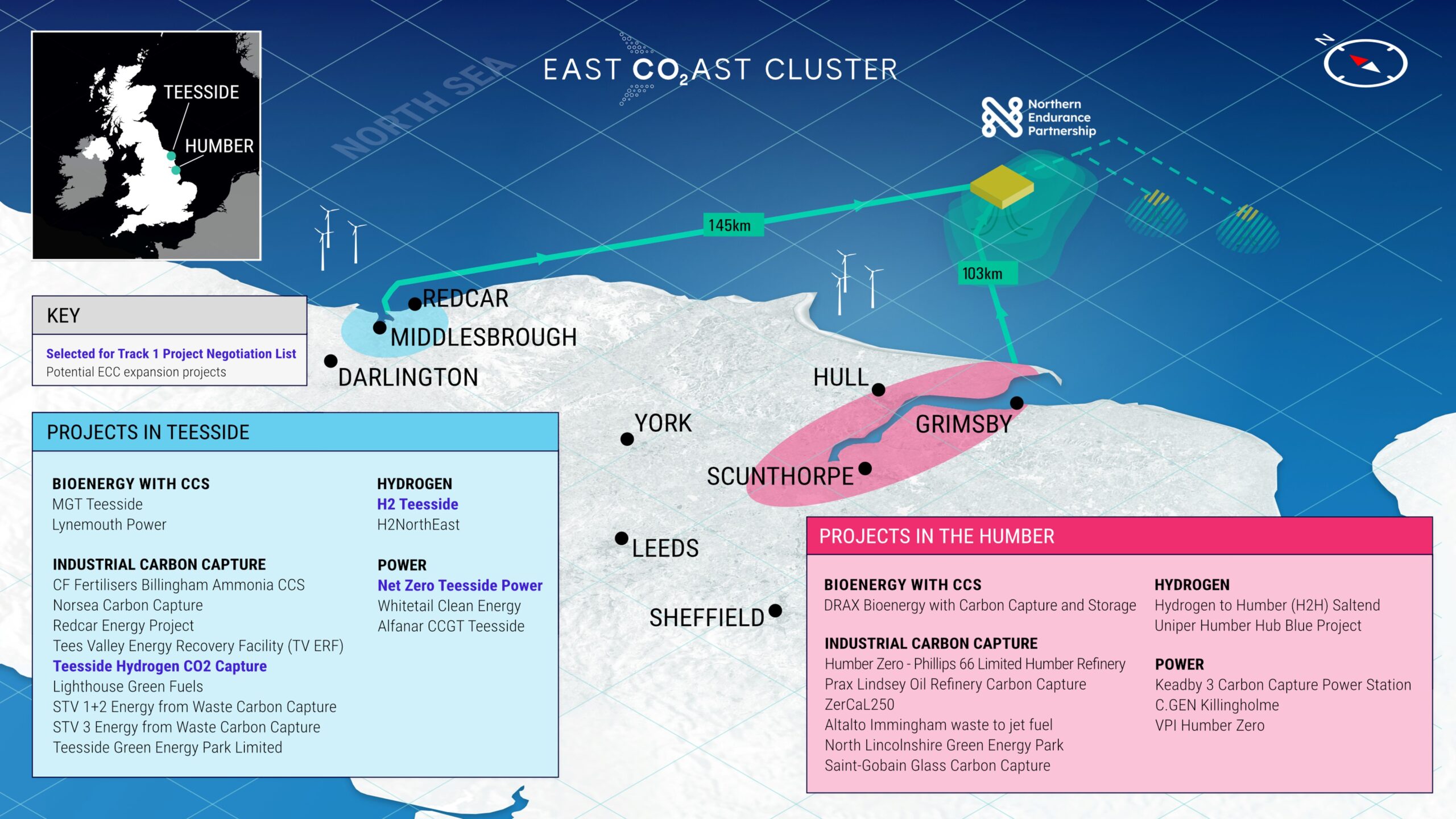

LIBERTY Steel selected for major UK carbon capture pipeline contract

LIBERTY Steel today announces that its Hartlepool pipes division has been selected for a major contract to supply pipelines to...

View Community

Community

Impress, Inspire, and Empower

How can we attract young people to the manufacturing and steel industry? That’s the big question, and the answer is...

View News

News

LIBERTY Bolton Aerospace Service Centre successfully passed the BSI Environmental audit

In October 2023, the LIBERTY Bolton Aerospace Service Centre achieved a notable milestone by successfully passing the BSI Environmental audit...

View News

News

Liberty Advanced Machining Centre: Where Steel Meets Innovation

If you’re curious about the art of turning steel into finely crafted landing gears, engine components, and more, a visit...

View Community

Community

LIBERTY Speciality Steels relaunched its Community Engagement Programme

LIBERTY Speciality Steels has recently relaunched its social Community Engagement Programme. Read more about its initiatives. School Engagement We work closely...

View Community

Community

Unlocking potential to transform the Manufacturing Industry

This September, LIBERTY Steel UK welcomed MP Miriam Cates alongside representatives from the Manufacturers’ Organisation Make UK and LIBERTY’s educational...

View News

News

LIBERTY Speciality Steels recruited 22 new apprentices

LIBERTY Speciality Steels recruited 22 new apprentices LIBERTY Specialty Steels has recently welcomed 22 apprentices to join the company this...

View Community

Community

James Brunt & LIBERTY UK: The Art of Steel

This summer, LIBERTY Steel UK hosted a very special guest at its Rotherham site – the British artist James Brunt....

View Community

Community

LIBERTY Speciality Steels and the University of Sheffield launch Carbon Capture Trials

On August 23rd, LIBERTY Speciality Steels, in conjunction with the University of Sheffield, started carbon capture trial at the LIBERTY...

View Community

Community

Over £5000 for Sheffield Children’s Hospital

A group of determined cyclists from LIBERTY Steel UK recently completed the challenging Trans Pennine Trail Coast to Coast bike...

View