Our ambition for Carbon Neutral Steel by 2030

Our CN30 ambition is to develop profitable, resilient businesses that are carbon neutral by 2030

"It's time to get serious about the environmental impact of producing steel."

Sanjeev Gupta, Executive Chairman, GFG Alliance

The steel industry is facing a trilemma

World Steel Association estimate of growth between 2012-2050

World Steel Association estimate of growth between 2012-2050

Clearly, this is a conflict and fundamental change is needed.

With this in mind, we have announced our ambition to become carbon neutral by 2030 – or as we call it, CN30.

Our ambition to be carbon neutral by 2030 is bold and demands a major transition from a heavy polluting industry to a modern carbon-neutral future. Climate change won’t wait so we are committed to taking action now. We don’t have all the answers, but we have a realistic, measurable and manageable path forward that will allow us to transform our production methods swiftly, steadily and economically. To reinvent the industry we believe, steel producers, policymakers and the financial community need to work together to deliver real sustainable change.

We welcome like-minds to join us on this exciting journey. We also invite you to take a look at our progress in our recent sustainability report.

Our plan to transition to GREENSTEEL

LIBERTY Steel produces steel across the globe through integrated steel facilities as well as recycled scrap based Electric Arc Furnaces (EAFs)

Around 40% of our steel is produced through the EAF route which we use in Australia, Poland, the UK and the US. Using electricity, our EAFs manufacture steel products with a significantly lower carbon emission level – more than 60% less CO2 per tonne of steel – compared to those made by traditional steelmaking methods.

Recycling scrap metal as the main feedstock into our EAFs allows us to use a local resource with a very low level of embedded carbon which further reduces emissions, saves on natural resources and diverts scrap from landfill.

The other 60% of our steelmaking processes – in Australia (Whyalla), the Czech Republic (Ostrava) and Romania (Galati) – use the traditional blast furnace (BF/BOF) route. This uses carbon (primarily from coal) as the primary source of transition fuel.

To achieve our ambition to become a carbon-neutral steelmaker by 2030, we have to transition our business away from using BFs while we further reduce the carbon emissions of our EAFs through the use of renewable electrical energy.

Through this transformation we will see a shift in our global production footprint as we reconfigure primary production locations to take advantage of renewable energy, new technologies, and access to raw materials, while keeping our meltshops and rolling mills close to their markets.

The GREENSTEEL transformation of our blast furnace facilities focuses on three main areas:

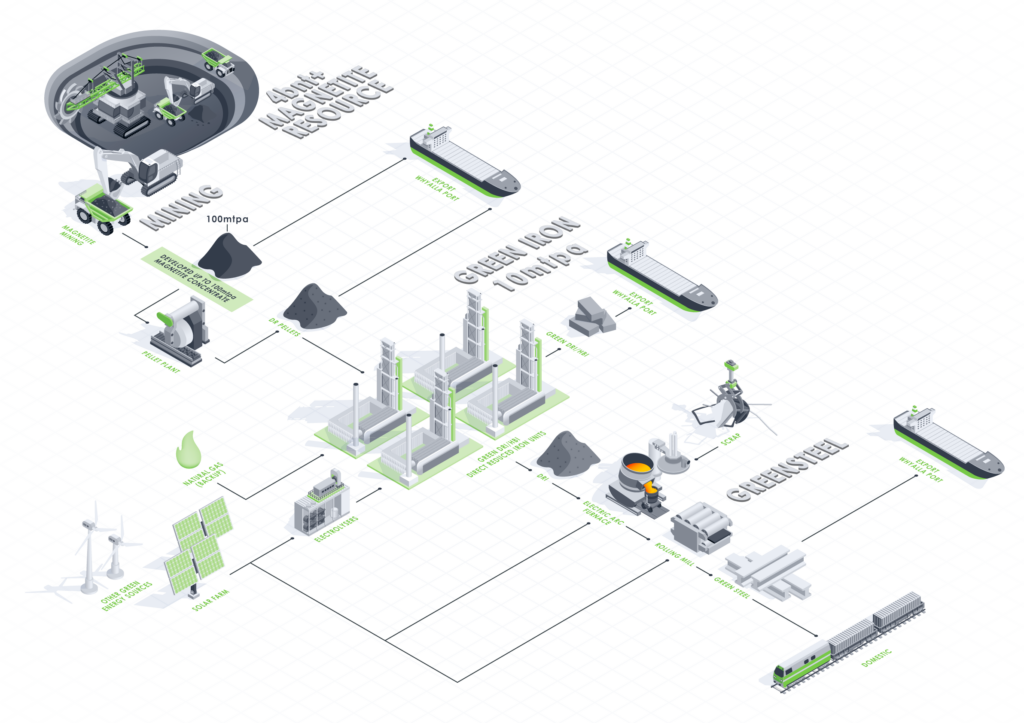

Our mines in Whyalla, South Australia provide us with access to abundant high quality magnetite ore – an essential ingredient for green iron and steel production. We will unlock our vast magnetite resource and convert it into two value add premium products: magnetite concentrate; and direct reduction (DR) quality pellets for use in the Direct Reduced Iron (DRI) process.

We will use renewable electricity like wind and solar to initially produce energy to power our plants and then to produce green hydrogen, which will replace carbon as the reducing agent in the direct reduction process. Natural gas will be a transition fuel as we move from carbon to hydrogen while commissioning and stabilising the new steelmaking processes.

We will replace our BFs with DRI units and our BOFs with EAFs. The DRI units will start with natural gas as the transition fuel but will then move to using Hydrogen when it is available. The product produced through the DRI units can also be converted to Hot Briquetted Iron (HBI), which can safely and affordably be transported across the globe as a bulk material.

Our global integrated steel operations by 2030

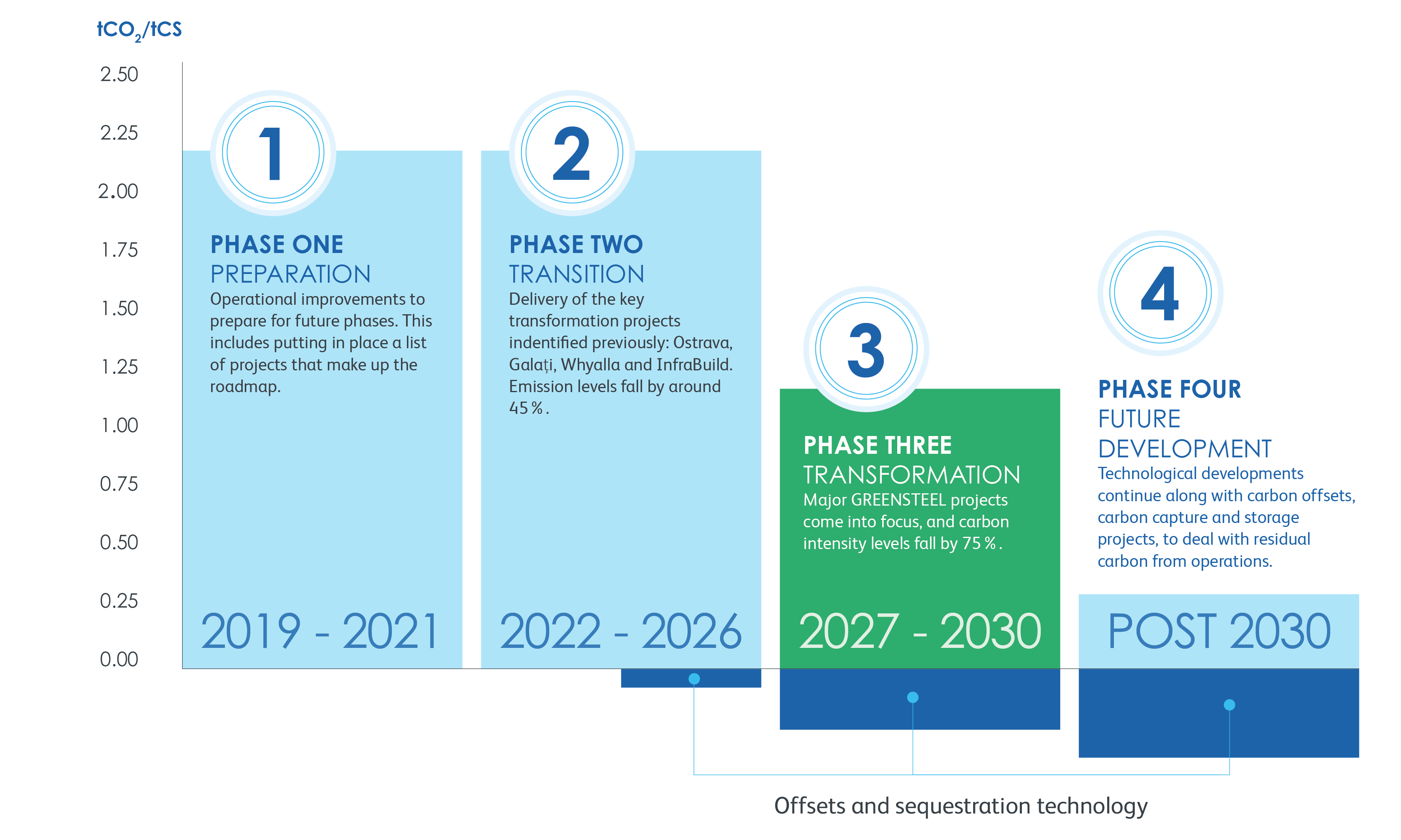

Our roadmap to carbon reduction

Our key projects

LIBERTY steel has taken significant steps in its transition to GREENSTEEL from its early achievements in producing Australia’s first DR Pellets to LIBERTY Ostrava’s procurement of two hybrid electric arc furnaces.

LIBERTY’s GREENSTEEL Journey Starts with Magnetite

We are putting in place the building blocks for our transition to GREENSTEEL with our magnetite expansion project in Australia, which is important because high-quality processed magnetite ore is essential to the DRI process for making GREENSTEEL.

Read more

LIBERTY Ostrava’s transformation to GREENSTEEL and CN30

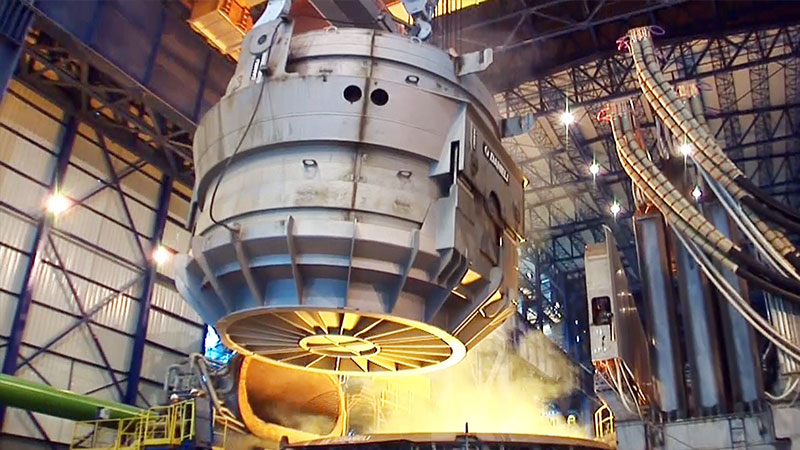

LIBERTY Ostrava aims to transform into a modern steel mill delivering an economically, environmentally and socially sustainable business with its GREENSTEEL transformation programme over the next eight years. The key element of that programme is the replacement of the steelwork’s four tandem furnaces with two new hybrid electric arc furnaces.

Read more

LIBERTY Galati GREENSTEEL transformation plan

LIBERTY Steel Group plans to invest in the LIBERTY Galati GREENSTEEL transformation programme over the next eight years. The key element of that programme is installation of two electric arc furnaces, a DRI plant and an integrated MI.DA minimill – with the potential to increase the production up to 4 MTPA.

Read moreOur CN30 news

View All Blog

Blog

Our Mission at COP 28 – Partnerships that accelerate action

Combating climate change will require meaningful collaboration between a host of nations, which is why COP28, to be held in Dubai, is so vital if it is...

View CN30

CN30

Prime Minister tours Whyalla Steelworks to witness its green steel transformation in action

Prime Minister Anthony Albanese has toured the Whyalla Steelworks as it marked another milestone in the journey to low carbon, green steel production. Mr...

View Blog

Blog

LIBERTY Steel UK spearheads Innovation Drive

From carbon capture to hydrogen pipelines: Explore how LIBERTY Steel UK leads the charge in innovation and carbon reduction, driving a sustainable future for the steel industry.

View Blog

Blog

Decarbonising steel in a connected world

Rita Monteiro – Global Head of Decarbonisation Hydrogen a potential driving force for low emissions iron and steel making and...

View Blog

Blog

Sanjeev Gupta heralds the ‘Hydrogen iron age’ during a keynote speech in Brisbane

Sanjeev Gupta has used a keynote address at the Australian Hydrogen Conference in Brisbane on the 25th May, to paint...

View CN30

CN30

The journey towards EU green steel

LIBERTY held a highly successful debate in Brussels on the “Future of the EU Steel Industry” with key EU decision...

View CN30

CN30

Infrabuild: Sustainable slab solution unlocking opportunities in residential construction

A world-first, locally-manufactured sustainable slab solution is revolutionising the way residential slabs are built and saving Australian home builders...

View CN30

CN30

Perth Australian Hydrogen Conference

Sanjeev Gupta, Executive Chairman of GFG Alliance and LIBERTY Steel Group, shares his views at the Australian Hydrogen Conference, Perth...

View CN30

CN30

LIBERTY Steel UK launches ecoke – a new method of electric steelmaking to reduce CO2 emissions

LIBERTY Steel UK has successfully completed trials of ecoke – a sustainable new raw material that can replace anthracite, the...

View CN30

CN30

LIBERTY makes historic investment in Ostrava’s GREENSTEEL transformation

LIBERTY Ostrava signs contract with Danieli for two hybrid electric arc furnaces New furnaces will reduce LIBERTY Ostrava’s emissions by...

View CN30

CN30

Reinventing Steel for a Sustainable Future

Sandip Biswas is Group Chief Investment Officer at GFG Alliance and Interim CEO, Primary Steel & Mining Europe & Australia...

View CN30

CN30

American Chamber of Commerce Adelaide, Keynote Speech

Sanjeev Gupta, Executive Chairman of GFG Alliance and LIBERTY Steel Group, shares his views at the American Chamber of Commerce,...

ViewInvesting in future generations

GREENSTEEL ACADEMY

As part of the CN30 ambition, we have created the GREENSTEEL Academy to help us to build the skills we need to sustain our industry for the long term and meet our CN30 strategic objectives. The GREENSTEEL Academy’s mission is simple: to engage, inspire and develop the workforce of today and tomorrow through innovative development programmes.

Read more

GFG Foundation

The GFG Foundation seeks to inspire, empower, and enable young people in industrial communities to reach their life and employment potential. We do this through running school programmes in areas where GFG Alliance has a significant presence. These programmes give students some important skills to help them towards being job-ready after school. These include STEM based learning programmes, designed to involve students in problem solving real-world issues that are happening in their local communities.

Read moreRelated publications

LIBERTY Steel Group’s Sustainability Report 2023 'Foundations for Change'

We are excited to present LIBERTY Steel Group’s second Sustainability Report. The report shares our strategy, provides data on our global impact, is open about the challenges we face and how we plan to address them, and outlines our approach to safety and the development of our people.

LIBERTY Steel Group’s first Sustainability Report 2022

We are very pleased to be able to share LIBERTY Steel Group’s first Sustainability Report, which outlines our plans to be an industry leader with an ambitious commitment to Environmental, Social and Governance (ESG) standards across our operations worldwide.

The investment case for GREENSTEEL in the UK

In 2021, Sustainable industry leader, GFG Alliance (GFG), owner of LIBERTY Steel Group, announced the launch of a major new three-way policy partnership with Green Alliance, the University of Sheffield Advanced Manufacturing Research Centre and Bright Blue.