LIBERTY Ostrava’s transformation to GREENSTEEL and CN30

LIBERTY Ostrava aims to transform into a modern steel mill delivering an economically, environmentally and socially sustainable business with its GREENSTEEL transformation programme over the next eight years.

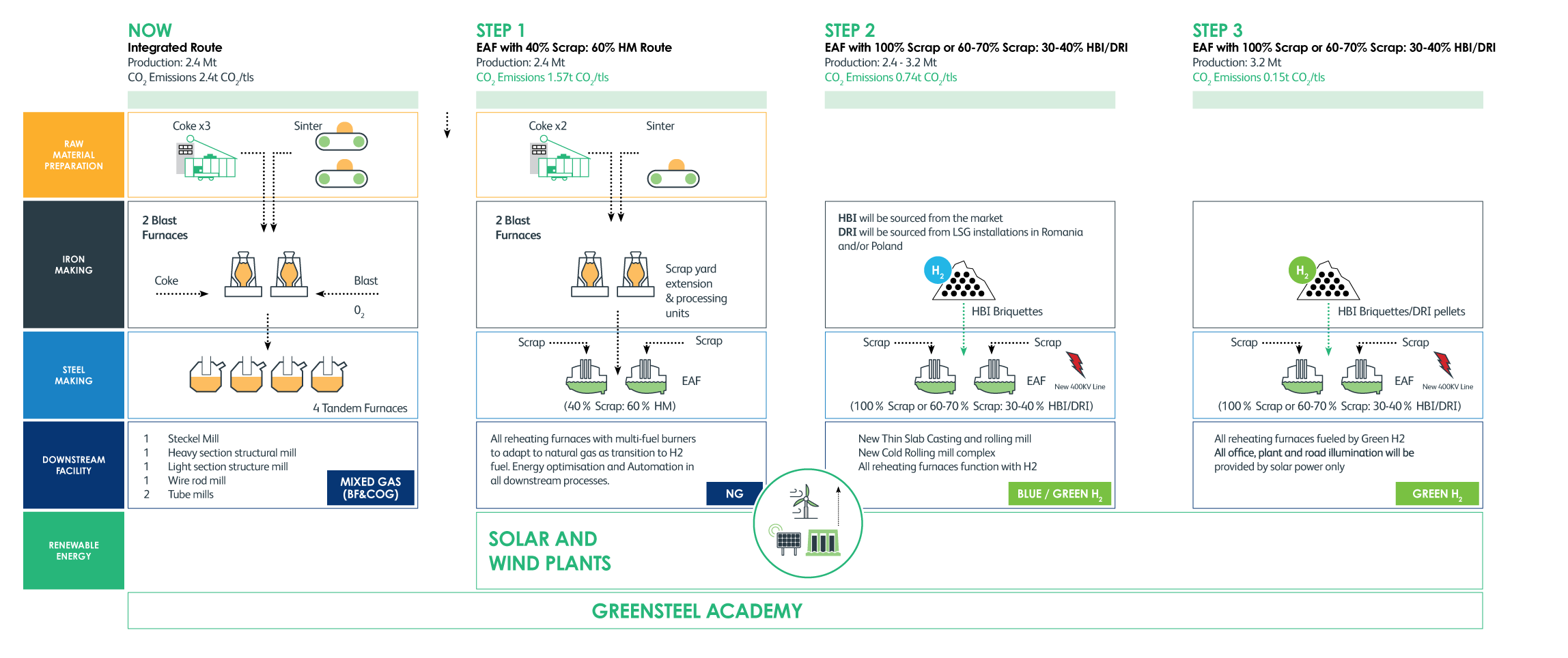

The key element of the programme will be the replacement of the steelwork’s existing four tandem furnaces with two hybrid electric arc furnaces, allowing the use of a higher volume of steel scrap and a range of different charge materials, reducing reliance on imported coal and iron ore and significantly reducing CO2 emissions. In addition to the modernisation of the steel shop, the transformation will also include an extensive modernisation of the steel rolling mills, which will improve the quality of steel and expand the product portfolio with high-added value products. The investment programme will also see the creation of a renewable power plant for electricity production as well as the development of the LIBERTY GREENSTEEL Academy.

Our GREENSTEEL programme will deliver:

| Modernisation of the steel shop with the installation of two Electric Arc Furnaces (EAFs) - reducing CO2 emissions per tonne of steel by up to 90% by 2030 | |

| Modernisation of the plant’s strategic Longs and Steckel mill to incorporate new technologies and digitalisation | |

| Installation of a new Thin Slab Casting & Rolling and new Cold Rolling Mill complex | |

| Renewable solar power for electricity | |

| Improved scrap capacity to feed the EAFs | |

| Green Hydrogen produced from renewable sources to be used in all currently NG-powered reheating processes | |

| Supported by the LIBERTY Ostrava GREENSTEEL Academy | |

| In line with GFG & LIBERTY Steel Group’s ambition to be carbon neutral by 2030 (CN30) |

Other key projects

LIBERTY’s GREENSTEEL Journey Starts with Magnetite

We are putting in place the building blocks for our transition to GREENSTEEL with our magnetite expansion project in Australia, which is important because high-quality processed magnetite ore is essential to the DRI process for making GREENSTEEL.

Read more

LIBERTY Galati GREENSTEEL transformation plan

LIBERTY Steel Group plans to invest in the LIBERTY Galati GREENSTEEL transformation programme over the next eight years. The key element of that programme is installation of two electric arc furnaces, a DRI plant and an integrated MI.DA minimill – with the potential to increase the production up to 4 MTPA.

Read moreOur CN30 news

View All CN30

CN30

The journey towards EU green steel

LIBERTY held a highly successful debate in Brussels on the “Future of the EU Steel Industry” with key EU decision...

View CN30

CN30

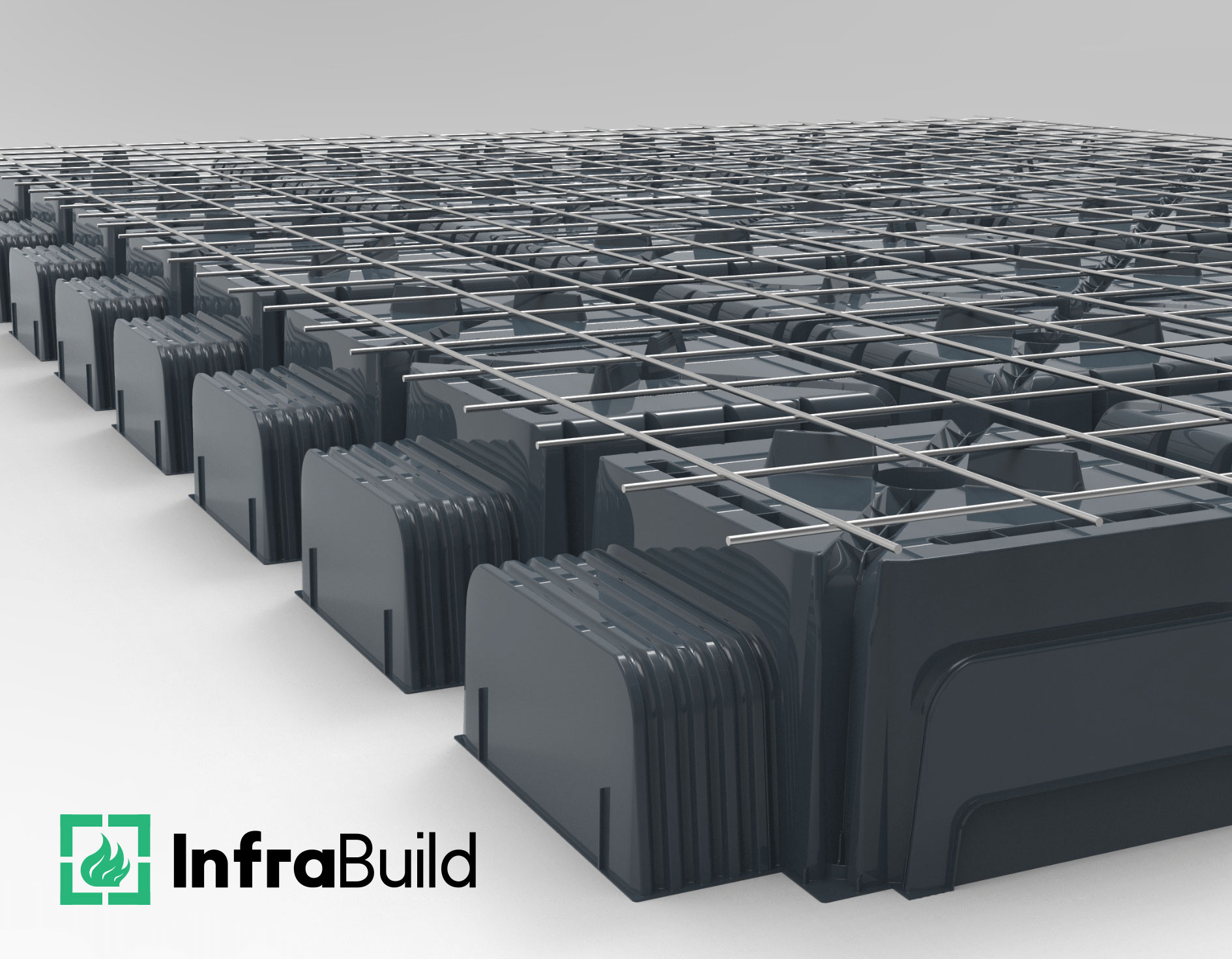

Infrabuild: Sustainable slab solution unlocking opportunities in residential construction

A world-first, locally-manufactured sustainable slab solution is revolutionising the way residential slabs are built and saving Australian home builders...

View CN30

CN30

Perth Australian Hydrogen Conference

Sanjeev Gupta, Executive Chairman of GFG Alliance and LIBERTY Steel Group, shares his views at the Australian Hydrogen Conference, Perth...

View CN30

CN30

LIBERTY Steel UK launches ecoke – a new method of electric steelmaking to reduce CO2 emissions

LIBERTY Steel UK has successfully completed trials of ecoke – a sustainable new raw material that can replace anthracite, the...

View CN30

CN30

LIBERTY makes historic investment in Ostrava’s GREENSTEEL transformation

LIBERTY Ostrava signs contract with Danieli for two hybrid electric arc furnaces New furnaces will reduce LIBERTY Ostrava’s emissions by...

View CN30

CN30

Reinventing Steel for a Sustainable Future

Sandip Biswas is Group Chief Investment Officer at GFG Alliance and Interim CEO, Primary Steel & Mining Europe & Australia...

View CN30

CN30

American Chamber of Commerce Adelaide, Keynote Speech

Sanjeev Gupta, Executive Chairman of GFG Alliance and LIBERTY Steel Group, shares his views at the American Chamber of Commerce,...

View CN30

CN30

Ziarul Financiar Investments for a Green Future in Romania

Four panels of experts from relevant fields discussed decarbonisation solutions and development opportunities for the Romanian industry, covering four major themes

View