A world-first, locally-manufactured sustainable slab solution is revolutionising the way residential slabs are built and saving Australian home builders time in the process.

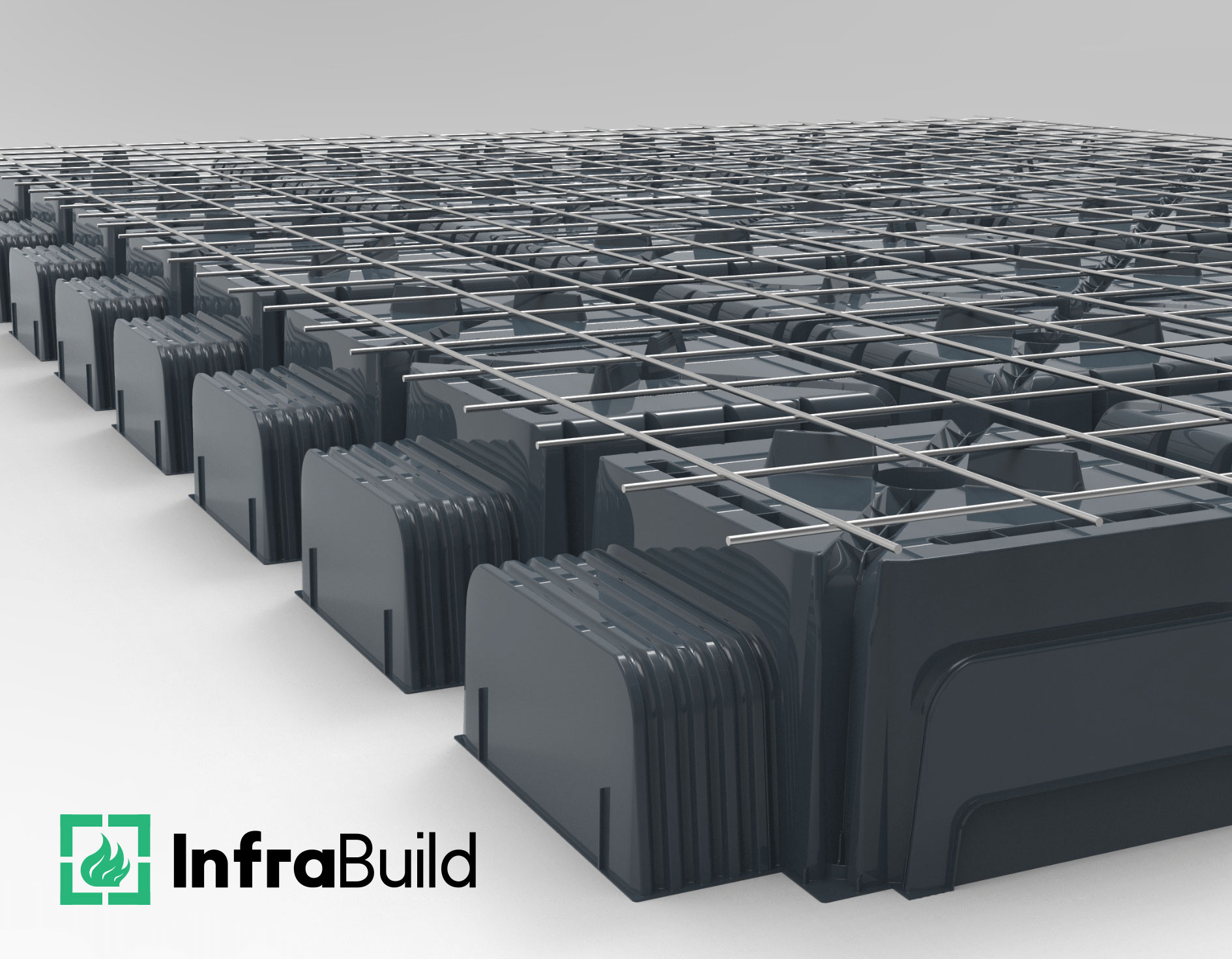

LOKPOD is a sustainable, environmentally friendly replacement for polystyrene, which comes with an in-built chairing system, eliminating the need for traditional bar chairs and spacers in concrete slabs.

The brainchild of Ross Bourke from the Australian Reinforcing Company (ARC), a brand of InfraBuild, LOKPOD is manufactured from recycled plastic and is a one to one substitution for polystyrene pods.

ARC General Manager Sean Mannering said the solution’s unique design, coupled with its sustainability credentials, had driven strong early interest from the residential construction market.

“LOKPOD simplifies and speeds up the slab building process for workers onsite with no engineering required and the interlocking installation ensuring each quadrant locks into the next when setting down,” Mr Mannering said.

“It is delivered through our local supply chain with just two small straps used to keep stacks together during transportation and no other packing material or pallets required, significantly reducing waste.

“The design is also quite compact, which means the product can be easily stacked resulting in it taking up less space on a construction site and eliminating the chances of it blowing away in the wind.”

Following a soft launch earlier this year, LOKPOD has been attracting attention across the industry and was recently awarded the 2022 HIA-CSR Hunter Housing and Kitchen & Bathroom Award for Product Innovation.

“This is the result of many years of collaborative research and testing, and has already been trialled successfully with some of the nation’s largest volume residential builders,’ Mr Mannering said.

“We’ve been servicing the Australian construction market for more than 100 years and we are focused on continuing to bring innovative solutions like LOKPOD to market to deliver better outcomes for our customers.

“The product will be available in a higher capacity in New South Wales from the New Year and we are looking to scale up production with a move into Victoria in the first half of 2023.”

As a proud Brand of InfraBuild, Australia’s largest vertically integrated steel manufacturing, distribution and recycling business, ARC has manufactured reinforcing steel for more than 100 years, contributing to some of the nation’s most iconic construction projects and backed by the largest distribution network of branches in Australia.

To this day, all ARC steel products remain 100 percent Australian-made and comply with international and Australian quality standards.

– ENDS-

Please contact us for any feedback or media enquiries about this content.

Latest News

View All Media Releases

Media Releases

LIBERTY proposes new measures to drive demand for UK steel production and stimulate investment

LIBERTY Steel’s submission to the UK Steel Strategy consultation has proposed decisive Government action in the form of strategic demand...

View Archived

Archived

Whyalla steelworks up and rolling again

Another milestone following blast furnace restart The resumption of steel production in the Whyalla Steelworks has reached another milestone with...

View Archived

Archived

Whyalla steel production restarts but GFG cautious

Whyalla Steelworks has cast its first steel following a 4-month shut down due to operational challenges and extensive repairs. The...

View Archived

Archived

Introducing the Steel Town Podcast: A glimpse into the heart of steelmaking in Whyalla

GFG Alliance has launched Steel Town, a new podcast series that takes listeners into the world of mining and steelmaking in...

View