If you’re curious about the art of turning steel into finely crafted landing gears, engine components, and more, a visit to Liberty Advanced Machining Centre (AMC) is a must. This place is where humans and robots team up, showcasing the pinnacle of technology. It’s a hub for cutting-edge machines and top-notch innovations, all within the UK.

AMC takes on complex projects that cater to a wide range of industries: Aerospace, Oil & Gas, Yellow Goods, Industrial Machinery, and General Engineering. The moment you step in, you’ll be amazed at how innovative and clean the steel industry can be.

Andrew Smedley, the Operations Manager at AMC, said: “Advanced Machining Centre adds a special touch to what customers receive. For instance, if an aerospace client needs specific products like landing gears or engines, they get exactly that when they work with LIBERTY. Unlike other steel companies that might provide just raw materials, we take it further. No need to hunt for additional suppliers to convert the steel into final products. We handle the downstream process, and that’s where our strength lies.”

At the heart of the centre are ten multitasking machines capable of performing multiple operations simultaneously – turning, milling, grinding, drilling, tapping, and deep-hole boring. This is all done with remarkable precision, premium quality, and impressive speed. Computer-controlled operations managed by skilled engineers ensure everything runs smoothly. Safety is paramount; each machine has its designated area marked by specific lines. If someone enters this area during operation, the robot stops to prevent accidents.

There’s also a precision grinding machine ensuring utmost accuracy, along with an inspection room where all parameters are meticulously checked against specifications.

Andrew shared, “Our order book is full, and we’re poised for a profitable year. We maintain strong, long-term partnerships with companies like NMB Minebea (UK) Ltd, Nammo Raufoss, Clean Power Hydrogen, Heroux-Devtek, while continuously welcoming new customers. The Aerospace Centre frequently suggests adding value by starting with first-stage machining at AMC. We can also modify bar diameters or offer pre-machined bars to external machining shops for finishing.”

When asked about Advanced Machining Centre’s success, Andrew Smedley emphasized, “It’s our people and the immense potential this centre holds. We have an exceptional, dedicated team that’s well-regarded by our customers. Coupled with top-notch equipment and software, we’re accredited in the aerospace industry, supplying to Boeing and Airbus supply chains through long-term agreements.”

Andrew continued, “And then there’s the potential. It’s enormous. We’re implementing continuous improvement projects and following 5S principles to keep things organised and safe. The setup is tidy, well-structured, and efficient. However, we’re aiming for more. We want to train people and shift their mindset to take these initiatives to a higher level. With the right strategy, investments, and skilled individuals, this potential is definitely within reach.”

We are excited to share that the Advanced Machining Centre, part of LIBERTY Steel UK, will be exhibiting at Advanced Engineering UK 1st and 2nd November. We will be showcasing our high value manufactured engineered components serving sectors such as Aerospace, Automotive, Oil & Gas, and General Engineering.

Our sales and technical teams will be there to discuss products and capabilities. Come and meet us at Stand N207!

For more info, visit 👇

https://lnkd.in/g9mmS-s

Tags

Latest News

View All Community

Community

Steel Industry Insight Day for Students

LIBERTY Speciality Steels and the GFG Foundation hosted students from Stocksbridge High School and High Storrs School at the Rotherham...

View News

News

A New Roof for our Green Future

LIBERTY Speciality Steel has started a significant repair project at the Melting Shop in Rotherham (ACP), marking an important step...

View News

News

Apprenticeship: Investing in the future

LIBERTY Steel UK has a long history of offering apprenticeships and setting apprentices up for life. We talked to LIBERTY...

View News

News

Apprenticeship Opportunities for 2025

LIBERTY Speciality Steels is excited to announce 19 new apprenticeship opportunities for 2025. We are looking for enthusiastic individuals to...

View News

News

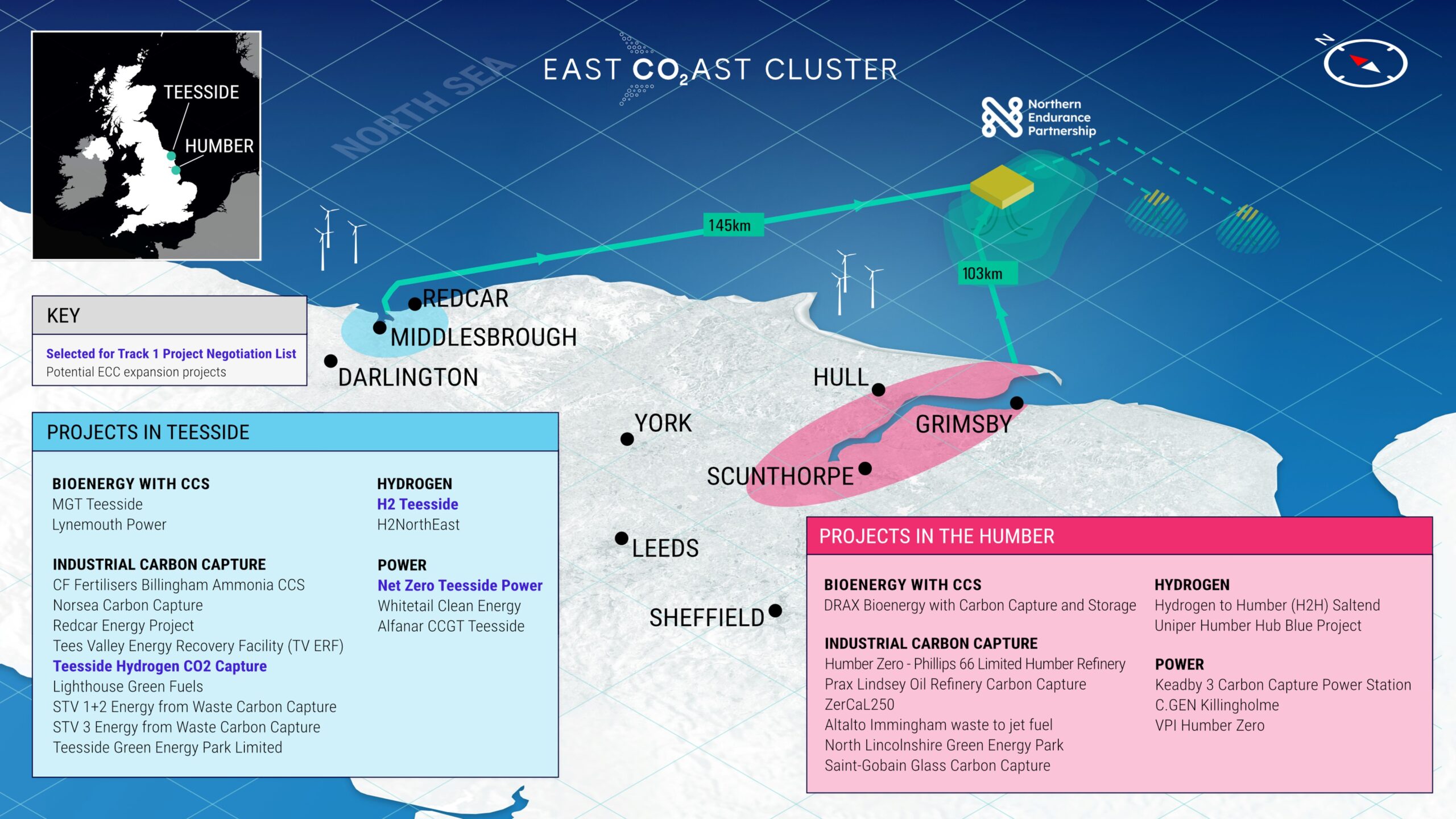

LIBERTY Pipes Hartlepool starts production for major UK energy infrastructure project

LIBERTY Steel UK’s pipes division in Hartlepool has started production on a major contract to supply pipelines for a key...

View News

News

LIBERTY Steel selected for major UK carbon capture pipeline contract

LIBERTY Steel today announces that its Hartlepool pipes division has been selected for a major contract to supply pipelines to...

View Community

Community

Impress, Inspire, and Empower

How can we attract young people to the manufacturing and steel industry? That’s the big question, and the answer is...

View News

News

LIBERTY Bolton Aerospace Service Centre successfully passed the BSI Environmental audit

In October 2023, the LIBERTY Bolton Aerospace Service Centre achieved a notable milestone by successfully passing the BSI Environmental audit...

View News

News

Liberty Advanced Machining Centre: Where Steel Meets Innovation

If you’re curious about the art of turning steel into finely crafted landing gears, engine components, and more, a visit...

View Community

Community

LIBERTY Speciality Steels relaunched its Community Engagement Programme

LIBERTY Speciality Steels has recently relaunched its social Community Engagement Programme. Read more about its initiatives. School Engagement We work closely...

View