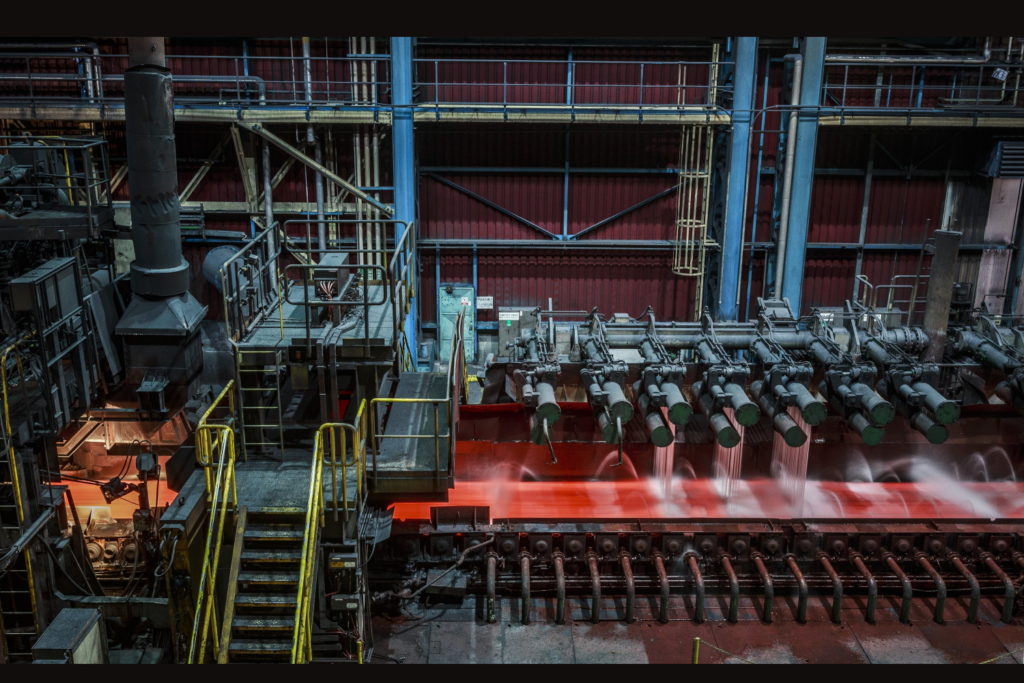

LIBERTY Ostrava is undertaking extensive modifications worth almost a billion crowns (EUR 33 million) to its hot strip mill, the only producer of hot rolled strip steel in the Czech Republic. The replacement of many technological parts by the end of 2023 with more modern ones will improve the reliability and sustainability of the operation of the plant’s Steckel mill, ensure the desired quality of its products and increase its capacity utilization to more than 1 million tonnes.

The hot strip rolling mill, otherwise known as the Steckel Mill, revamp is taking place in several stages due to the long lead times of spare parts and the durations required for the repair. The programme started this spring and will last until the end of 2023. After this year’s shutdown in November, 1,400 existing hydraulic elements were replaced by more modern ones. Next May, further modifications will include the installation of two X-ray thickness gauges, the replacement of furnace coilers and cooling towers of laminar cooling. The automation program, which provides model control of the mill will also be modernized allowing more accurate prediction of rolling forces and temperatures.

Consequently, in 2023, functional blocks of bending in stands as well as hydraulic capsules will be replaced by more modern components. In parallel, the functions of the mill’s descalers, frits and roll cooling mechanisms will be improved. An equally important part of the program will be the gradual replacement of all auxiliary regulated drives on the track. In the spring and autumn of 2023, the installation of new the technological elements will require at least a two-week shutdown of the mill.

Sambit Beborta, Director of Technology for LIBERTY Steel Group Europe, who is leading the team responsible for the project’s preparation, said: “This important investment will increase the quality of LIBERTY Ostrava’s steel strips as well as the reliability and efficiency of the rolling mill and enable us to produce over 1 million tonnes of flat products per year.”

Jan Pudich, Director of the hot strip mill in LIBERTY Ostrava added: “The implementation of the range of individual upgrades will improve the mechanical properties of the hot rolled strip, remove surface defects and ensure precise adherence to its geometric shape. This will allow us to offer our Czech and international customers even better quality strips as and when they need it. “

The Steckel mill was built in the 1990s as a completely new operation and at that time, the Ostrava steelworks was the first facility in Europe to implement the technology of strip production from liquid steel. On one side of the 200-meter-long hall liquid steel in ladles is transferred directly from the steel shop, on the other side the already coiled and strapped steel strips are transported. The production takes place in a relatively small space and the whole process takes about two hours. The advantage of the Ostrava steelworks´ Steckel mill is a high degree of flexibility, so the operation is economic even with a low annual production volume, which allows the company to respond to market requirements in a flexible way.

Further information from:

| Barbora Černá Dvořáková Head of communications LIBERTY Ostrava |

+420 606 774 346 | barbora.cerna-dvorakova@libertysteelgroup.com |

| Paddy Toyne-Sewell Head of Communications – Europe GFG Alliance |

+44 (0) 7767 498 195 | Patrick.toyne-sewell@gfgalliance.com |

Note to the editors:

LIBERTY Ostrava is an integrated steel business with an annual production capacity of approximately 3.6 million tonnes per annum serving primarily construction, machinery and oil & gas industries. The company is a domestic leader in the manufacture of road barriers and tubes. In addition to the Czech market, it supplies its products to more than 40 countries around the world. Together with its subsidiaries in Ostrava, the company has 6,000 employees. The company manufactures its products with a minimum possible environmental footprint. The mill is part of LIBERTY Steel Group.

GFG Alliance is a collection of global businesses and investments owned by Sanjeev Gupta and his family. The Alliance is structured into three core industrial pillars; LIBERTY Steel Group, ALVANCE Aluminium Group and SIMEC Energy Group, independent of each other yet united through shared values and a purpose to create a sustainable future for industry and society. GFG Alliance employs 35,000 people, across 10 countries and has revenues of USD $20bn. GFG Alliance is a leader in sustainable industry with a mission to become Carbon Neutral by 2030 (CN30).

| Liberty Steel Group |

Latest News

View All Press Releases

Press Releases

LIBERTY Ostrava has started implementation of its restructuring plan

The company does not foresee further cooperation with Tameh LIBERTY Ostrava will implement the Plan B option of its restructuring...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan vote confirmed by notary

The appointed notary has today confirmed that the required majority of LIBERTY Ostrava’s eligible creditors have officially approved its robust...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan overwhelmingly approved by creditors

LIBERTY Ostrava’s creditors have approved its restructuring plan with over 90% voting in favour of the plan, comfortably clearing the...

View Press Releases

Press Releases

Change to employer disruptions

As it continues to deliver its robust restructuring plan and preserve jobs, LIBERTY Ostrava has taken the pragmatic decision to...

View Press Releases

Press Releases

LIBERTY Ostrava granted a general moratorium

LIBERTY Ostrava has today been granted a general “preventative restructuring” moratorium (“general moratorium”) to provide the time to discuss its...

View Press Releases

Press Releases

LIBERTY Ostrava optimisation plan update

LIBERTY Ostrava has today provided its key stakeholders with details of its optimisation plan which will improve the operational, commercial...

View Press Releases

Press Releases

LIBERTY Ostrava update on proposed optimisation plan

LIBERTY Ostrava has today provided an update on its proposed optimisation plan which will lead to a long term, sustainable...

View News

News

LIBERTY Ostrava update

Like many other energy-intensive companies in Czechia, LIBERTY Ostrava has faced some major operational and financial issues over the last...

View News

News

LIBERTY Ostrava’s giant mold starts its challenging journey to Britain

A giant industrial mold, produced by the foundry of LIBERTY Engineering Products Ostrava for its British customer Sheffield Forgemasters, today...

View Press Releases

Press Releases

LIBERTY Ostrava’s mine supports underpinning the reconstruction of Prague’s sewer system

LIBERTY Ostrava is supplying 400 mine support arches to a major sewerage reconstruction project in Prague. It is one of...

View