Ostrava, 29 April 2020 – This year marks 60 years since the first wire was rolled out at the Ostrava steelworks. Since 1960 when the production was launched, the mill has manufactured more than 19 million tons of steel wire. Currently the track manufactures up to 520 kT of wire rod per year. It is primarily used in construction, e.g. as concrete reinforcement but it is also used as mesh or for production of shopping carts, nails or plastic window knobs.

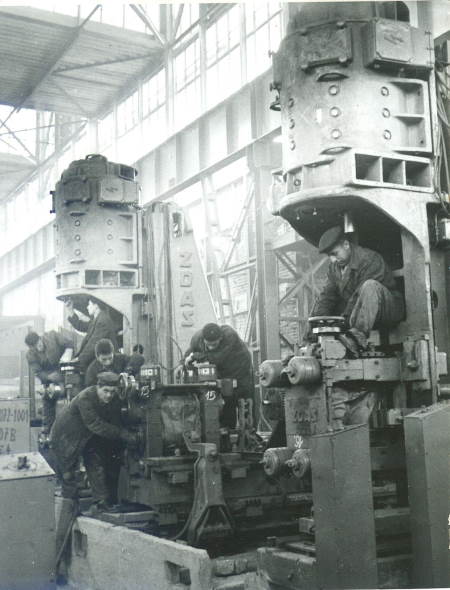

The construction of the rolling mill was kick-offed in 1957. The operation assembly was completed in early 1960 and in the spring of the same year a trial run was started. The first wire of an optimum quality was rolled out on 29 April 1960. The production capacity of the track was projected for 460,000 tons of wire per year. However, the output did not exceed 30 tons per hour in the first years of operation, only 67 200 tons of wire were produced during the first year of operation. The operation has not reached its projected capacity before 1971 when more than 458,000 tons of steel wire was manufactured for the very first time.

“As the time passed the product portfolio manufactured at the wire rod mill changed. When the production started, the wire of 8-10 mm in diameter was rolled. Except for wire production an operation of torsion machines producing rebars TOROS was launched. In 1968 production of wire out of free-cutting steel was started. Nowadays the wire rod mill produces hot rolled wire rod of 5.5 – 14 mm in diameter,” says Jiří Zbořil, head of the wire rod mill at LIBERTY Ostrava.

Over the sixty years the track has gone through a number of revamps. In 2016 it was equipped with a new giant press for wire coils withdrawal and completion directly from the production line and subsequent pressing into compact bundles. The investment into cold stretching in 2018 enabled production of ribbed wire rod in coils which increased the competitiveness of the mill on the rebar market and the share of high added value products.

“The recent investment at the wire rod mill is the shears worth CZK 40 million thanks to which we manage to save production costs and increase the reliability and productivity of the whole wire rod mill,” adds Zbořil.

The wire rod mill is part of the strategic investment announced in February 2020. The plan is to modernize the mill to increase the coil weight and also to increase the portion of quality wire rod to 40% of the annual mill´s output. The Project team are working on the modernization concept, with commissioning expected in 2023.

LIBERTY Ostrava is an integrated steel business with an annual production capacity of approximately 3.6 million tonnes per annum serving construction, machinery and oil & gas industries. The company is a domestic leader in the manufacture of road barriers and tubes. In addition to the Czech market, it supplies its products to more than 40 countries around the world. Together with its subsidiaries in Ostrava, the company has 6,000 employees. The company manufactures its products with a minimum possible environmental footprint. It is part of LIBERTY Steel Group, which is part of GFG Alliance, a collection of global businesses and investments owned by Sanjeev Gupta and his family. The Alliance is structured into three core industrial pillars: LIBERTY Steel Group, ALVANCE Aluminium Group and SIMEC Energy Group. Headquartered in London, GFG Alliance employs 35,000 people, across 10 countries and has revenues of USD $20bn.

|

|

|

|

|

|

|

|

LIBERTY Ostrava a.s.

LIBERTY Ostrava a.s.

Barbora Černá Dvořáková

Head of Communicaions

T +420 595 683 390

M +420 606 774 346

barbora.cerna-dvorakova@libertysteelgroup.com

Latest News

View All Press Releases

Press Releases

LIBERTY Ostrava has started implementation of its restructuring plan

The company does not foresee further cooperation with Tameh LIBERTY Ostrava will implement the Plan B option of its restructuring...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan vote confirmed by notary

The appointed notary has today confirmed that the required majority of LIBERTY Ostrava’s eligible creditors have officially approved its robust...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan overwhelmingly approved by creditors

LIBERTY Ostrava’s creditors have approved its restructuring plan with over 90% voting in favour of the plan, comfortably clearing the...

View Press Releases

Press Releases

Change to employer disruptions

As it continues to deliver its robust restructuring plan and preserve jobs, LIBERTY Ostrava has taken the pragmatic decision to...

View Press Releases

Press Releases

LIBERTY Ostrava granted a general moratorium

LIBERTY Ostrava has today been granted a general “preventative restructuring” moratorium (“general moratorium”) to provide the time to discuss its...

View Press Releases

Press Releases

LIBERTY Ostrava optimisation plan update

LIBERTY Ostrava has today provided its key stakeholders with details of its optimisation plan which will improve the operational, commercial...

View Press Releases

Press Releases

LIBERTY Ostrava update on proposed optimisation plan

LIBERTY Ostrava has today provided an update on its proposed optimisation plan which will lead to a long term, sustainable...

View News

News

LIBERTY Ostrava update

Like many other energy-intensive companies in Czechia, LIBERTY Ostrava has faced some major operational and financial issues over the last...

View News

News

LIBERTY Ostrava’s giant mold starts its challenging journey to Britain

A giant industrial mold, produced by the foundry of LIBERTY Engineering Products Ostrava for its British customer Sheffield Forgemasters, today...

View Press Releases

Press Releases

LIBERTY Ostrava’s mine supports underpinning the reconstruction of Prague’s sewer system

LIBERTY Ostrava is supplying 400 mine support arches to a major sewerage reconstruction project in Prague. It is one of...

View