Ostrava, 25 October 2019 –Liberty Ostrava steel mill tested an innovative single side steel safety barrier. The new type of safety barrier which is lighter but has better parameters than its predecessor passed a crash test at the airport in Kámen u Pacova. The goal of the crash tests is to test this passive safety element and its properties in a real situation so that only reliable and approved restraint systems which have obtained the necessary certification after the tests could be installed on the roads. According to the Czech police statistics, safety barriers from the Ostrava steel mill have contributed to decrease in the number of fatal road accidents by 38 % over the last 15 years, and by 49 % as regards accidents with serious consequences. Liberty Ostrava is going to start production of the new type of safety barriers this year.

„Safety barriers help reduce the number of fatal and serious traffic accidents. They are installed at dangerous sections or roads with potentially dangerous obstacles nearby such as big trees or rocks. Before the new innovated type of safety barrier finds its way from the production line to the roads it needs to pass a number of practical tests including a crash test,” says Richard Toman, head of Mine Supports and Safety Barriers at Liberty Ostrava.

During a crash test the prototype restraint system component which is to be tested is installed at a test site. Then, two crashes by remote-controlled motor vehicles are conducted. These may include a light and a heavy passenger car, a light or heavy lorry or a bus depending on the desired retaining standards determined by both the weight of the testing vehicle and its velocity at the moment of the crash. The majority of certified crash tests are carried out at speeds between 65 and 110 km/h at the crash angle between 8 to 20 degrees. In this case of safety barriers tests with an H3 restrain standard a light passenger car weighing 900 kg and a lorry weighing 16,000 kg were used.

Whether or not the crash test was successful we find out nearly immediately. “At the crash, the restraint system must be able to intercept the vehicle and change the direction of its movement. It must also ensure appropriate safety of passengers inside the vehicle as well as of other road users at the same time. During the crash the restraint system creates what is called a pocket which will adjust the energy of the impact and lead the vehicle back into its lane with the direction of its original movement. The lengthwise elements of the restraint system must not fall apart and no part of the restraint system may get inside the vehicle either. Neither the vehicle nor any of its parts may overcome the restraint system barrier during the crash. A number of further safety parameters are also observed, such as the dynamic sag of the crash barrier, the working width of the barrier or the crash intensity index which refers to the rate of dangerous speed-up for the passengers inside the vehicle during the crash. This is measured using a dummy at the driver’s position,” says Roman Ondruška, assistant director of Technical Engineering Services branch and lead restraint systems specialist from Technical and Test Institute for Construction Prague, who was in charge of conducting the crash tests in Kámen u Pacova.

“The success rate of safety barriers from Liberty Ostrava in the crash tests is around 90 %. Currently, we do a computer simulation of the crash for every new or innovated road barrier for us to minimise the risk of failure at the crash test. Over the last 15 years we have done 40 crash tests of road barriers, which amounts to an approximate 80 crashes. Each one of these crashes depending on the type of the safety barrier costs between 4.5 – 6.5 million CZK,” says Toman.

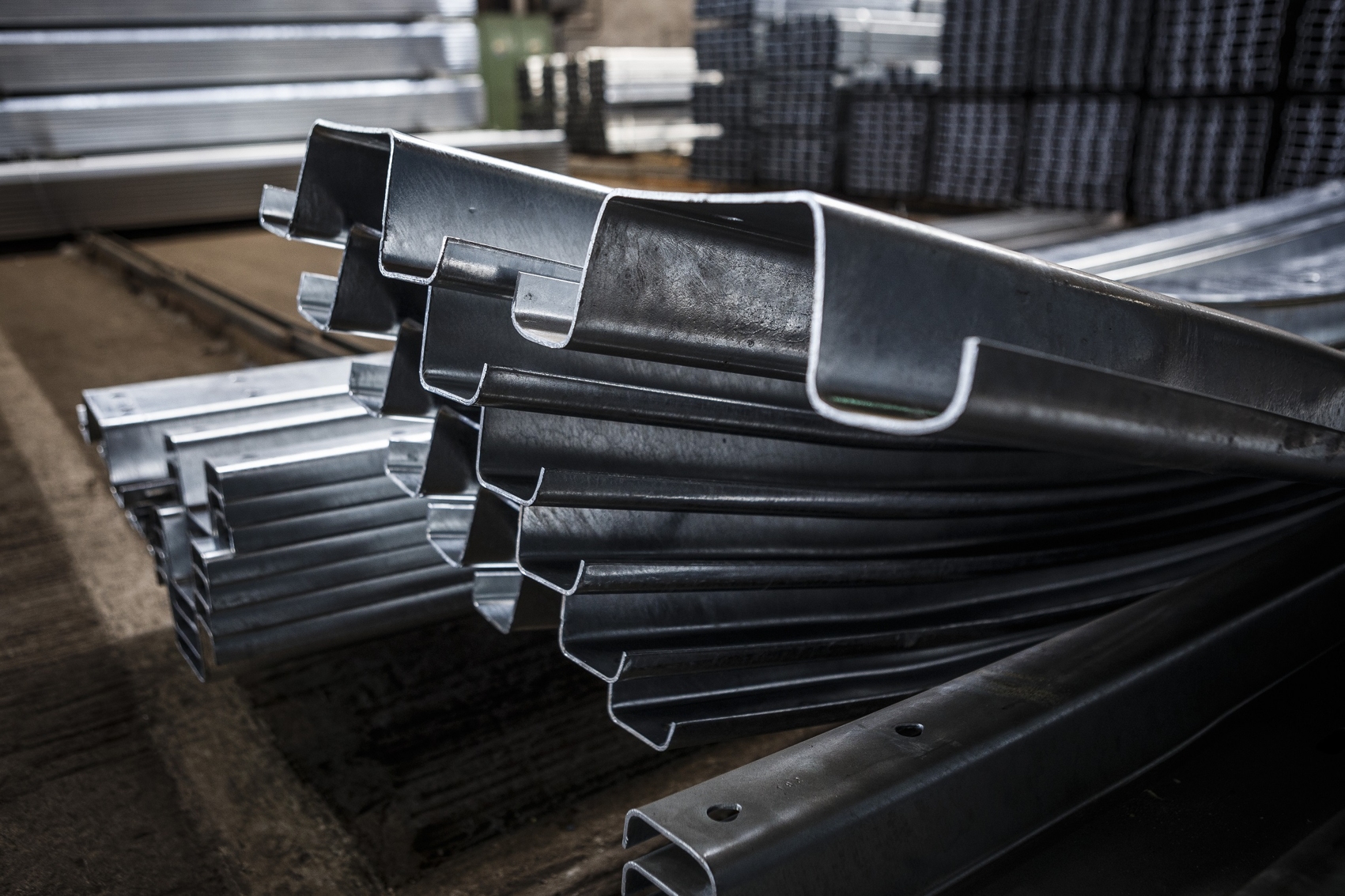

The Liberty Ostrava steel mill is the producer of 5 types of safety barriers. These include single side and double side safety barriers, bridge and hand-railing safety barriers and barriers with increased protection for motorcyclists. Altogether, they make up a total of 33 restraint systems[1]. Several new or innovated restraint systems have been developed over the last years. Apart from the design, also the material of the safety barriers has undergone innovation. For example, micro-alloyed steel, which is stronger, is used. That makes it possible to make the safety barriers 50 % thinner. Thanks to enhanced endurance, the safety of the lighter road barrier is the same and often the parameters are even better. The novelty of the last few years is the motorcyclist safety barrier equipped with a bottom flange. This protects motorcyclists from passing below the barrier which may cause serious injuries. At the same time, it absorbs a part of the motorcyclist’s kinetic energy and thus reduces the effects of the crash. In cooperation with the university of Zaragoza, the Ostrava steel mill participated in the development of SMART safety barrier equipped with three types of built-in sensors. These can assess the seriousness of the accident. Consequently, we have cooperated on the development of the SMARTER safety barrier that can also ensure the activation of a drone that captures and sends a report about the current situation to rescue units.

The safe conduct of all of road users still remains the key safety element on the road. This factor is, nevertheless, the least reliable. Consequently, it is necessary to adhere to passive safety on the roads. This is, to a huge extent, secured by safety barriers.

Interesting facts about safety barriers from Liberty Ostrava

- Liberty Ostrava is the biggest producer of steel safety barriers. For more than four decades the steel mill had been the only producer of steel safety barriers in the Czech Republic. The majority of safety barriers on Czech higher-class roads and motorways come from Ostrava.

- Every year the steel mill produces approximately 1,000 km of steel safety barriers. Since 1968, more than 45 thousand kilometres have been made. That would be, with some reserve, long enough to stretch around the equator.

- Safety barriers from Ostrava are mostly sold on the domestic market (more than 50 % of the production). But they are also sold in Slovakia or Lithuania.

- The most common type of safety barriers on Czech roads is the NH4 type, which has been manufactured at the steel mill since July 1968. Therefore, newer types of safety barriers are made so that they can be either directly connected to this type or alternatively with the use of transitional components.

- The reliability of a certified restraint system can be disrupted by incorrect installation or use of unoriginal components. A safety element can thus turn into a dangerous obstacle that can rupture during the crash, get inside the vehicle and cause serious or even fatal injuries to passengers. Therefore, our specialists ensure regular checks of the structures as well as do random checking of the systems installed in accordance with the assignment of General Directorate for National Motorways and Highways and the road network operators. If a safety issue is revealed they promptly inform the responsible road network operators and the Czech Trade Inspection Authority (CTIA).

- During the checks, our specialists have discovered numerous cases of forged components in the restraint systems. Therefore, the mill continuously changes the marking of road barrier components as a way of protection against forgery.

Liberty Ostrava a.s. is an integrated steel business with a production capacity of 3.6 million tonnes of steel. At present it annually produces c. 2.2 million tonnes of steel, which is mainly used in construction, machinery and oil & gas industries. The company is a domestic leader in the manufacture of road barriers and tubes. In addition to the Czech market, it supplies its products to more than 40 countries around the world. Together with its subsidiaries, the company has 6,300 employees. The 2018 average monthly income was CZK 39,180. As a result of the above-standard greening, the company manufactures its products with a minimum possible environmental footprint. It is part of Liberty Steel, a global steel and mining business. Liberty Steel is part of the GFG Alliance, a global group of energy, mining, metals, engineering, logistics, and financial services businesses, headquartered in London, with a presence in around 30 countries worldwide. The Alliance has a global workforce of around 30,000 people and a turnover exceeding US$ 20 billion.

[1] The restraint system consists of lower bars, posts, distance components, or also transitional or dilatational components, and beads, including bead reducers, handrail panelling, handrails etc.

LIBERTY Ostrava a.s.

LIBERTY Ostrava a.s.

Barbora Černá Dvořáková

Head of Communicaions

T +420 595 683 390

M +420 606 774 346

barbora.cerna-dvorakova@libertysteelgroup.com

Latest News

View All Press Releases

Press Releases

LIBERTY Ostrava has started implementation of its restructuring plan

The company does not foresee further cooperation with Tameh LIBERTY Ostrava will implement the Plan B option of its restructuring...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan vote confirmed by notary

The appointed notary has today confirmed that the required majority of LIBERTY Ostrava’s eligible creditors have officially approved its robust...

View Press Releases

Press Releases

LIBERTY Ostrava restructuring plan overwhelmingly approved by creditors

LIBERTY Ostrava’s creditors have approved its restructuring plan with over 90% voting in favour of the plan, comfortably clearing the...

View Press Releases

Press Releases

Change to employer disruptions

As it continues to deliver its robust restructuring plan and preserve jobs, LIBERTY Ostrava has taken the pragmatic decision to...

View Press Releases

Press Releases

LIBERTY Ostrava granted a general moratorium

LIBERTY Ostrava has today been granted a general “preventative restructuring” moratorium (“general moratorium”) to provide the time to discuss its...

View Press Releases

Press Releases

LIBERTY Ostrava optimisation plan update

LIBERTY Ostrava has today provided its key stakeholders with details of its optimisation plan which will improve the operational, commercial...

View Press Releases

Press Releases

LIBERTY Ostrava update on proposed optimisation plan

LIBERTY Ostrava has today provided an update on its proposed optimisation plan which will lead to a long term, sustainable...

View News

News

LIBERTY Ostrava update

Like many other energy-intensive companies in Czechia, LIBERTY Ostrava has faced some major operational and financial issues over the last...

View News

News

LIBERTY Ostrava’s giant mold starts its challenging journey to Britain

A giant industrial mold, produced by the foundry of LIBERTY Engineering Products Ostrava for its British customer Sheffield Forgemasters, today...

View Press Releases

Press Releases

LIBERTY Ostrava’s mine supports underpinning the reconstruction of Prague’s sewer system

LIBERTY Ostrava is supplying 400 mine support arches to a major sewerage reconstruction project in Prague. It is one of...

View