Course Module Discover GREENSTEEL General Information

The world evolves and technologies change rapidly. Today's students need to know not only the methods and information currently applicable, but especially the innovative techniques and technologies that will be used when they start their careers.

Discover GREENSTEEL

Discover GREENSTEEL is an accredited course program, developed by LIBERTY Galati specialists, dedicated to both students and college graduates who are interested in discovering the technologies of the future of green steel manufacturing.

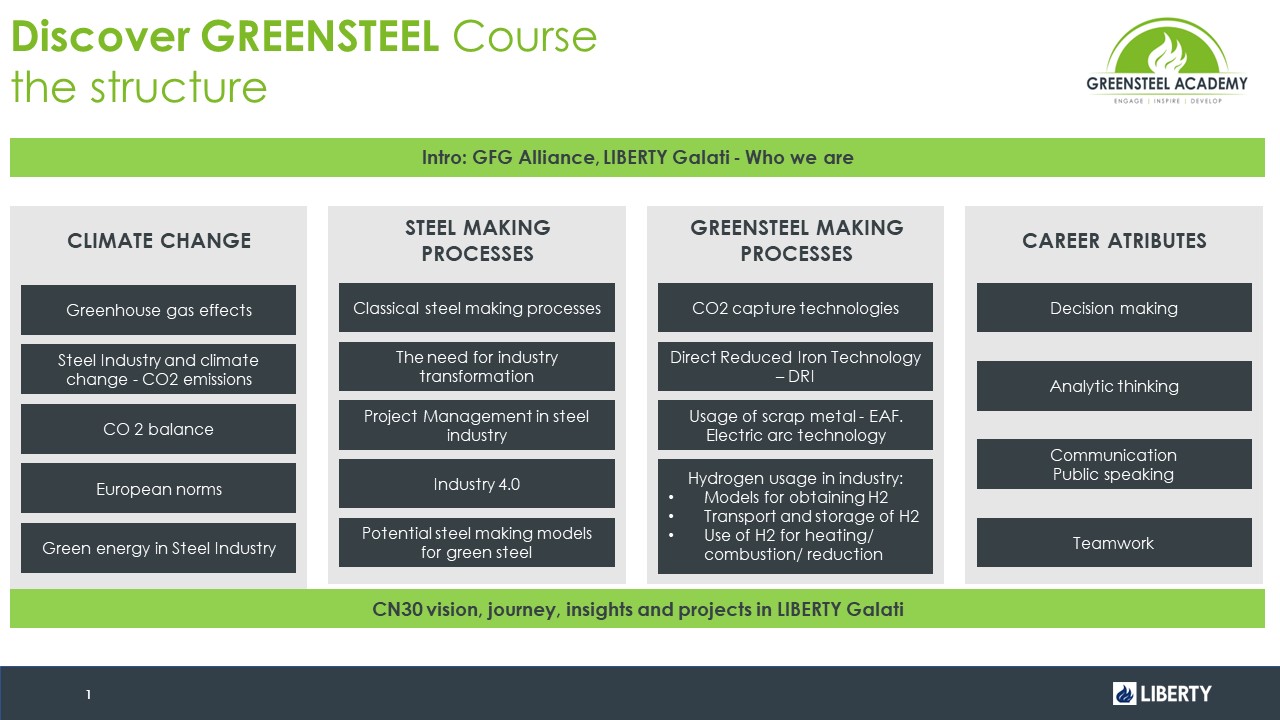

The module includes four areas of study:

- climate change,

- traditional steelmaking processes,

- the new GREENSTEEL technologies and

- a segment where students can develop their professional skills, such as analytical thinking, decision making, communication and collaboration.

Students will have the opportunity to learn about the new GREENSTEEL technologies: carbon dioxide capture and storage, direct reduction of iron (DRI), the use of hydrogen and green energy in the steel industry and not only by having as lecturers LIBERTY Galați specialists who have worked to program development.

Climate change is part of the current global context. This topic shows us how urgent the need for transformation has become.

The effects of climate change are already being felt around the world. They are expected to become more frequent and more intense in the coming decades.

If we do not act, then Europe could face, already in the lifetime of our children, with:

- 40% reduction in the volume of water available in the southern regions of Europe

- 2.2 million people at risk of coastal flooding every year

- annual economic losses amounting to EUR 190 billion

These climate changes have the power to transform our planet, affecting our health and food and water supplies. The bigger the problems, the more difficult and expensive it will be to fix them. That is why the best option is to act early to combat climate change.

Module 1 content:

- Greenhouse gas effects

- Steel Industry and climate change – CO2 emissions

- CO 2 balance

- European norms

- Green energy in Steel Industry

If you already want to learn more about climate change, we invite you to take, an on-line training module, developed by LIBERTY specialists, on this subject.

You can complete the course by clicking here.

LIBERTY Galaţi specialists in the field will speak extensively in this course about the classic steelmaking technologies: the conventional route, secondary metallurgy, and current steelmaking technologies.

By completing this module students will be able to learn more about the need and transformation in the steel industry, about project management, Industry 4.0, and potential models for greensteel making.

Module 2 content:

- Classical steel making processes

- The need for industry transformation

- Project Management in steel industry

- Industry 4.0

- Potential steel making models for green steel

In module 3, students will have the opportunity to learn about the new GREENSTEEL technologies: carbon capture and storage, direct reduction of iron (DRI), the use of hydrogen and green energy in the steel industry and more.

Module 3 content:

- CO2 capture technologies

- Direct Reduced Iron Technology – DRI

- Usage of scrap metal – EAF. Electric arc technology

- Hydrogen usage in industry

- Models for obtaining H2

- Transport and storage of H2

- Use of H2 for heating/ combustion/ reduction

There is certainly interest in the skills and competencies required for career success. The career skills module is developed to reveal the secrets to becoming your best self.

Module 3 content:

- Decision making

- Analytic thinking

- Communication

- Public speaking

- Teamwork and collaboration

PARTNERSHIP WITH THE EDUCATIONAL ENVIRONMENT

In June 2020, Sanjeev Gupta, Executive Chairman LIBERY Steel Group and GFG Alliance and Prof. Dr. Lucian Georgescu, Rector of “Dănărea de Jos” University, signed a Memorandum for the establishment of the GREENSTEEL Academy, a project that aims to develop educational projects and encourage young people to join the steel industry to contribute to the development of sustainable production methods.

Mihaela Vereș, Human Resources Manager at LIBERTY Galati, said: “As we prepare for the industry of the future, neutral in carbon emissions, it is important to collaborate with elite universities in Romania to train the specialists of the future. Two years ago, LIBERTY signed a partnership with “Dunărea de Jos” University in Galati to develop a series of programs. Today we are launching – for the first time – a GREENSTEEL module for students who will have access to future-oriented education and career opportunities in the steel industry. The new generation will work in a modern, digitalized, automated and sustainable industry, and our aim for students is to acquire the technical and professional skills that will help them in their careers.”

Prof. Lucian Georgescu, Rector of “Dănărea de Jos” University: “As partners, we are happy to join LIBERTY Galati in the journey towards a steel industry with a neutral carbon footprint and to put future generations at the center of it. Our university’s priority is to provide students with new opportunities for learning and development. On this occasion, I want to encourage young people to actively contribute to creating a sustainable future.”

We invite you to visit the webpage of our partners “Universitatea Dănărea de Jos” Galati

www.ugal.ro

CONTACT

Do you want to know more about the program, or do you have questions?

Please contact us at: descoperagreensteel.galati@libertysteelgroup.com

Do you want to participate in the program?

You can find out more also by visiting the page of Dunărea de Jos University

Competențe și abilități în domeniul obținerii oțelului verde (ugal.ro)

Careers

Scholarships

Since 2014, the company started the annual Scholarships Program for the best students in the last years of studies who...

Read More

Organizational Development

Read More

Get a qualification

In 2014, the Galaţi Steel Plant started an educational programme to attract new young workers and to support the local...

Read More