- 25/01/2022

- CN30

Ziarul Financiar Investments for a Green Future in Romania

The future of Romanian industry, whose major part is represented by the steel-making sector, was the subject of today’s (25 Jan 22) discussions at the conference “Romanian Industry: Investments for a Green Future“, held in Bucharest.

The event, hosted by the national newspaper Ziarul Financiar in partnership with LIBERTY Steel Group, aimed at bringing together Romanian and European decision-makers, financial institutions and major industry companies to jointly identify solutions to the urgent need to reduce carbon emissions while endorsing the heavy sector of the economy.

Four panels of experts from relevant fields discussed decarbonisation solutions and development opportunities for the Romanian industry, covering four major themes:

- Industry of the future

- Investing for the future: How do we finance all these projects?

- European funds and projects

- The workforce of the future

The debates were attended by the Prime Minister of Romania, the Minister of Economy, Secretaries of State in the Ministry of Energy, representatives of the European Bank for Reconstruction and Development and other banks, as well as leading companies in industry, academia and social partners.

The event was broadly covered by the Romanian media, including an article on the front page of Ziarul Financiar.

Sanjeev Gupta, Executive Chairman of LIBERTY Steel Group along with other senior officials of the Group, took the opportunity to share the GREENSTEEL vision, the core of our long-term development strategy, which offers Romania the opportunity to pioneer the green industrial revolution in Europe. “We now know hydrogen provides the key to a carbon-neutral steelmaking process. Hydrogen can be used in place of coking coal as a reducing agent to produce sponge iron – with the by-product being water. Currently, however, the production of hydrogen is challenging and costly. Each stage, from storage to liquefying, shipping and re-gassing, adds to the cost of a ton of hydrogen – on top of the capital costs of technology and infrastructure.

But by using hydrogen to make GREENSTEEL we can solve the storage and transport challenges and bring down the cost by producing hydrogen at scale, using renewable energy, and using it there and then through co-location and close proximity to the steelworks. Hydrogen lies at the heart of our GREENSTEEL transformation plans at Galati. We’ve spent significant resources to date on the engineering and design work to produce low-carbon GREENSTEEL. We plan to develop a DRI plant, with a 2.5 million tons capacity as well as installing two electric arc furnaces, supported by a major wind and solar renewable energy program.

These investments will reduce CO2 emissions per ton of steel produced by up to 80%, with emissions dropping to minimal levels once the DRI plant uses green hydrogen rather than natural gas as the reductant fuel. The building blocks are all there for the plant’s transformation to carbon neutrality by 2030”, Sanjeev Gupta explained in a message for the conference.

Latest News

View All Media Releases

Media Releases

LIBERTY appoints Thomas Gangl as CEO of its European business

LIBERTY Steel Group (“LIBERTY”) has appointed international sustainability leader Thomas Gangl as the Chief Executive Officer of its European business,...

View Media Releases

Media Releases

LIBERTY announces UK strategic steel plan after signing new creditor framework agreement

LIBERTY today announces the strategic plan for its UK steel assets after signing a new framework agreement (“the framework”) with its major creditors. The new framework comes after...

View Media Releases

Media Releases

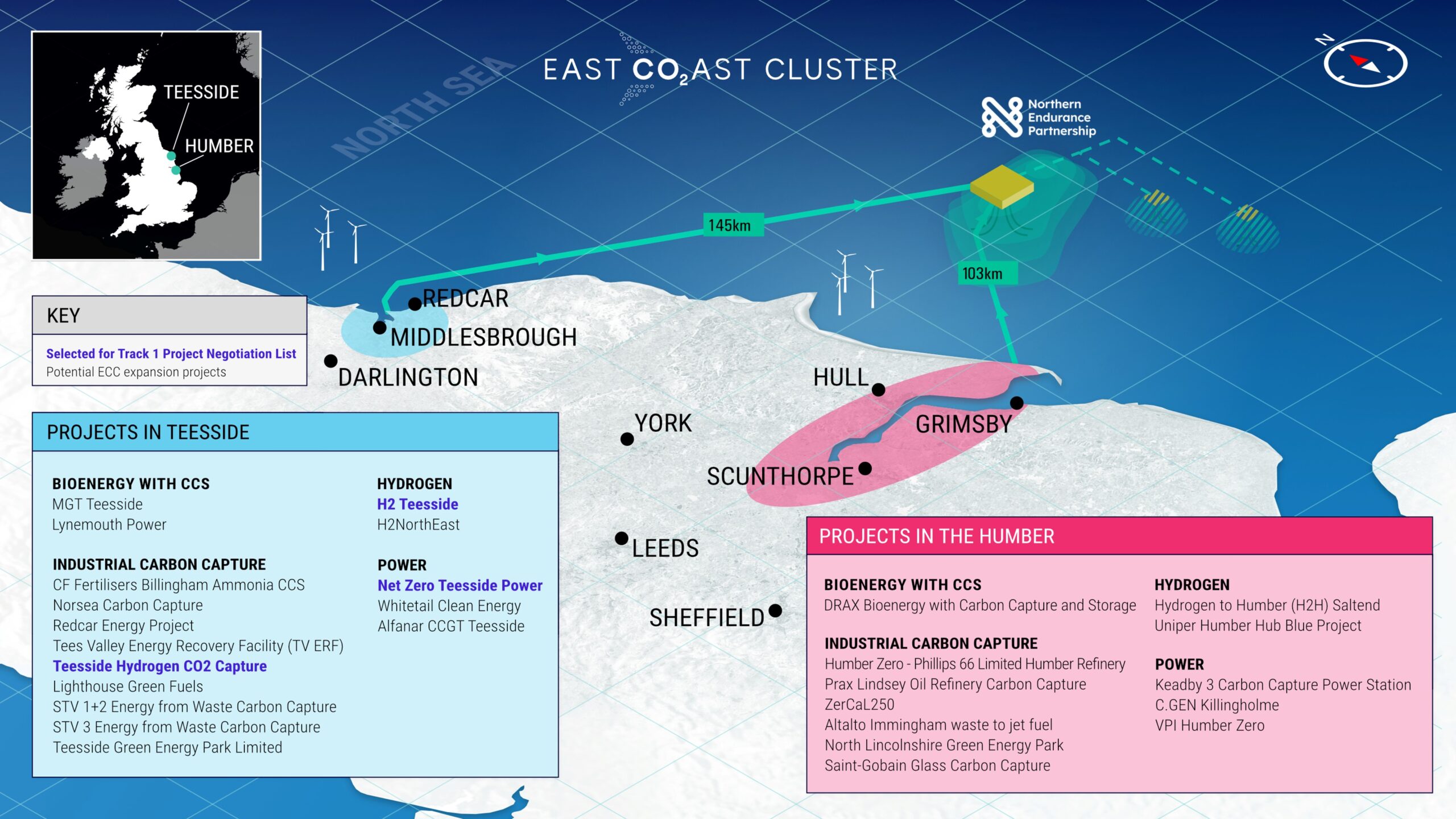

LIBERTY Steel selected for major UK carbon capture pipeline contract

LIBERTY Steel today announces that its Hartlepool pipes division has been selected for a major contract to supply pipelines to...

View Media Releases

Media Releases

GFG Alliance Signs Landmark Deals In Whyalla

Agreement on hydrogen and memorandum of understanding with Santos for gas Landmark Hydrogen Offtake agreement with South Australian Government MOU...

View