- 21/06/2017

- Media Releases

Liberty aims for higher altitude in global aerospace market following £100m acquisition

Britain’s leading producer of speciality steels aims to put the aerospace market at the heart of its drive for worldwide growth over the coming years, its new chief executive told industry leaders during this week’s Paris Air Show.

During a gathering of around 100 key aerospace executives in the French capital last night (June 20th), Jon Bolton, CEO of Liberty Speciality Steels, told guests the aircraft manufacturing supply-chain offered huge opportunities for steel producers who have a global vision and a strategy of innovation.

He said Liberty would continue to invest in advanced equipment and work more closely with supply-chain partners in order to be at the forefront of product innovation and serve an industry hungry for solutions to the challenges of reducing fuel consumption, lowering cost and meeting environmental obligations.

Mr Bolton and other senior company executives were meeting the aerospace representatives only weeks after Liberty acquired the UK-headquartered speciality steels business from Tata in a £100m deal and announced its intentions to build on its aerospace market share North America and Europe and expand its presence in Asia.

They pointed to latest Boeing projections that 41,000 new aircraft will be needed by the year 2036, with 40% of demand coming from Europe and North America and 38% from Asia. Steel accounts for almost a fifth of all material used in aircraft manufacture, and the total annual world market for these materials is estimated to be approaching $13 billion.

Demand from Asia is expected to result in the expansion of manufacturing supply chains in India and China, where Liberty Speciality Steels already has key service centres.

The Liberty Speciality Steels CEO added: “Our aerospace business is growing year on year and we are investing to ensure we continue to develop and supply the highest quality steels for this demanding and sophisticated market. Key to serving this growing sector is global coverage, and we are confident that our manufacturing and service centres across the world will enable us to provide the high level of support required.”

Making high-purity steels and alloys for the aerospace sector is a growing part of Liberty’s business, a trend that is expected to accelerate following the installation of a state-of-the-art vacuum induction melting (VIM) furnace at its plant in Stocksbridge near Sheffield and investment in its Advanced Machining Centre in neighbouring Rotherham.

The introduction of the VIM furnace enables the company to deliver the highest purity stainless steels and alloys, providing greater production flexibility, close control over compositional elements and removal of dissolved gases such as Nitrogen and Hydrogen.

Liberty’s product innovation includes research into powder metallurgy as part of the £18m government backed CASCADE project, which will produce metallic powders to develop near-net shape additive manufacturing for precision components. Key supply chain partners are also part of that project.

Latest News

View All Media Releases

Media Releases

LIBERTY appoints Thomas Gangl as CEO of its European business

LIBERTY Steel Group (“LIBERTY”) has appointed international sustainability leader Thomas Gangl as the Chief Executive Officer of its European business,...

View Media Releases

Media Releases

LIBERTY announces UK strategic steel plan after signing new creditor framework agreement

LIBERTY today announces the strategic plan for its UK steel assets after signing a new framework agreement (“the framework”) with its major creditors. The new framework comes after...

View Media Releases

Media Releases

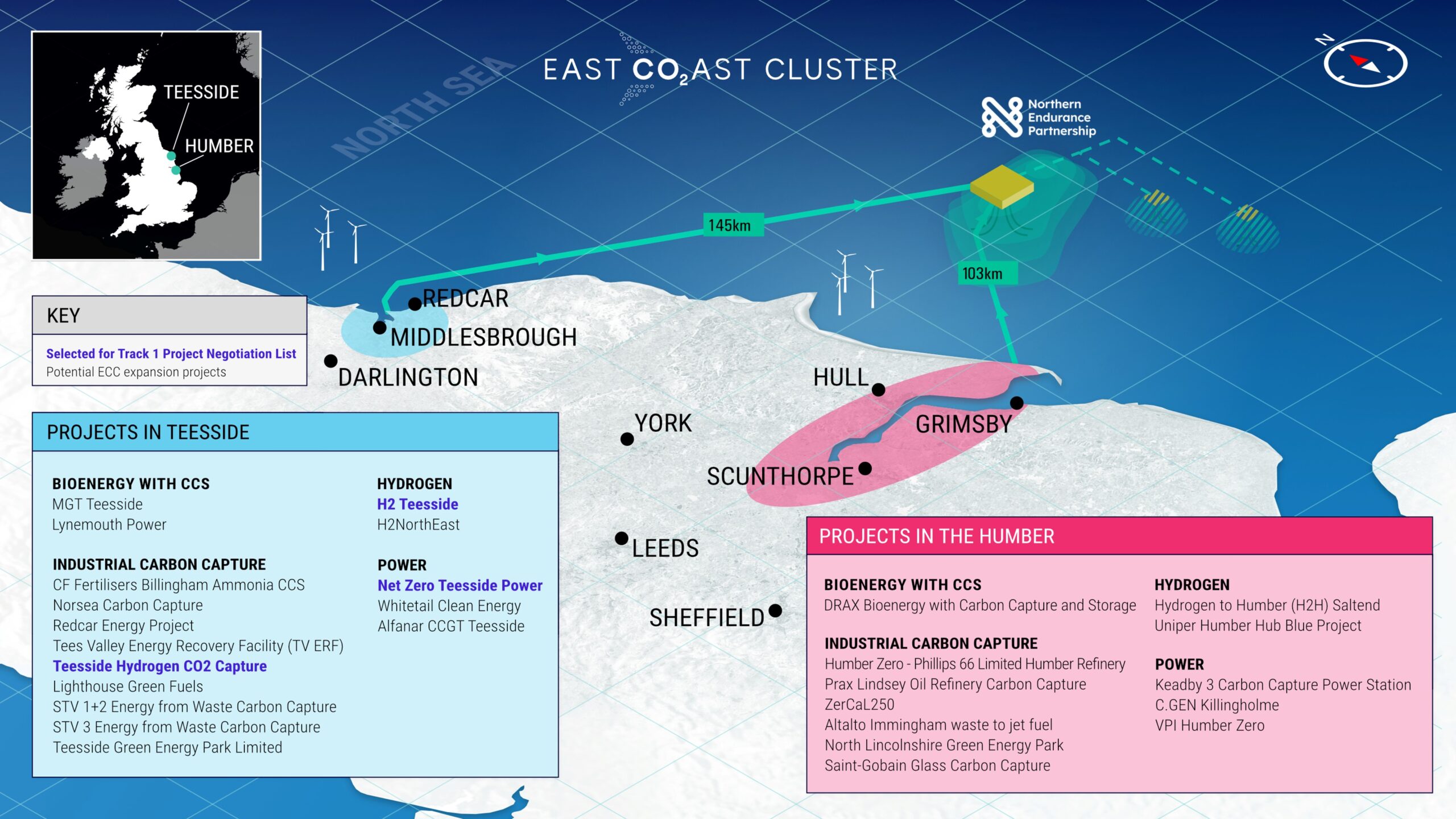

LIBERTY Steel selected for major UK carbon capture pipeline contract

LIBERTY Steel today announces that its Hartlepool pipes division has been selected for a major contract to supply pipelines to...

View Media Releases

Media Releases

GFG Alliance Signs Landmark Deals In Whyalla

Agreement on hydrogen and memorandum of understanding with Santos for gas Landmark Hydrogen Offtake agreement with South Australian Government MOU...

View